Introduction

Inductively Coupled Plasma Optical Emission Spectroscopy, or ICP-OES, is an analytical technique determining the elemental content of various materials. Here, a high-temperature plasma excites atoms in the sample, and the measured light at specific wavelengths allows one to identify and quantify elements contained within the material. This method is highly beneficial in material science in analyzing metals, alloys, ceramics, and polymers for accurate and quick results. ICP-OES is extensively used for quality control, material characterization, and trace element detection in materials to ensure their purity and performance. It is essential for aerospace, automotive, electronics, and energy industries as these require accurate elemental analysis for product development and reliability.

Scope

ICP-OES in material science is applied to provide an accurate elemental analysis of trace elements and ensure material quality. This technique identifies impurities that may reduce performance properties, such as strength or corrosion resistance. Thus, this technique facilitates the development of new materials, including their verification for specifications. Furthermore, ICP-OES contributes to environmental monitoring and recycling by identifying contaminants and pollutants.

Principle and working of ICP OES

In inductively coupled plasma-oxygen emission spectroscopy, an inductively coupled plasma excites atoms of a sample. An energy source supplies argon gas energized into the plasma state. The plasma contains a high particle density; its temperature ranges from 5,000 to 10,000 K. Then, the sample will be introduced into the plasma, where it dries, melts, and vaporizes fast as the gas molecules are energized; they undergo atomization and ionization. This process makes them emit electromagnetic radiation, which is the basis for the analysis. The light emitted passes through optical components that separate the various wavelengths. A detector measures the intensity of each wavelength, which is proportional to the concentration of the analyte being measured. Calibration standards are used to establish the relationship between light intensity and concentration of elements, where it is possible to calculate the accurate measurement through the mathematical function.

Structure of an ICP OES device

The ICP-OES process is simple: first, it generates plasma, then introduces the sample to excite the atoms, and later separates and measures the emitted radiation. The following description details how these steps are implemented through the technical components of an ICP-OES system.

| Aspect | Description |

| Plasma torch | This component is required to maintain the plasma. It comprises a torch with an injector to inject a sample atomized from the sample introduction system. |

| High-frequency generator | A high-frequency generator provides energy to sustain the plasma. It works at 40 or 27 MHz, which is internationally prescribed for this purpose. |

| Sample insertion system | Several components work together in this process. A peristaltic pump conveys the measurement solution to the atomizer, where a gas stream breaks the fluid into droplets. Downstream is the spray chamber, where larger aerosol droplets are filtered out. This injector is connected to the torch system. |

| Transfer optics | The transfer optics are not designed to split the wavelengths. They are exclusively used to convey the radiation to the dispersing optics. |

| Monochromator/ polychromator | The separation of component wavelengths can be done in two ways: With a monochromator or polychromator. ICP-OES requires an optical system to distinguish between adjacent lines with substantial precision. |

Sample Size

A typical solid sample should be 250 mg and 1 gram, with solution volumes ranging from 2 to 10 mL.

Result

The results obtained through ICP-OES offer detailed and quantitative information about a sample’s elemental content. Element concentration is measured across an expansive range, from trace to significant levels.

Applications

- In material science, ICP-OES is used for the elemental analysis of metals, alloys, ceramics, and polymers to ensure they comply with performance and quality standards.

- It detects trace contaminants in raw materials and final products, assisting in quality control in the manufacturing process.

- Failure analysis through ICP-OES helps determine the elemental causes of material failure, which gives an insight into product defects and guides design improvements.

- It is applied in recycling and waste management by analyzing metal concentrations in scrap materials or waste products to ensure proper recycling processes.

- ICP-OES helps develop new materials in research and development by providing detailed data regarding elemental composition and guiding material design for specific properties.

Conclusion

Inductively coupled Plasma Optical Emission Spectroscopy is one of material science’s most crucial elemental analysis techniques. Its importance ensures quality, safety, and performance in metals, alloys, ceramics, and polymers. This technique can detect trace elements and impurities to help support quality control, failure analysis, and the development of new materials. Optimizing the manufacturing process with ICP-OES enhances product design and contributes to environmental sustainability through recycling.

FAQs

Inductively Coupled Plasma Optical Emission Spectroscopy can analyze various sample types, including aqueous solutions, organic liquids, and solids. However, these samples must be prepared in a form compatible with the ICP-OES system.

ICP-OES generally offers detection limits that are two to three orders of magnitude higher than ICP-MS. Most elements are typically found within the range of 1-10 ppb.

ICP-OES usually has higher detection limits, ranging from parts per million (ppm) to parts per billion (ppb). ICP-MS, however, has much lower detection limits, often in the parts per trillion (ppt) range, which makes it more sensitive for trace element analysis.

The plasma in ICP-OES has a high temperature (5,000–10,000 K). It effectively vaporizes, atomizes, and excites atoms from a sample. The excited atoms emit characteristic light, whose spectrum allows for determining elemental composition.

Aerospace, automotive, energy, electronics, and environmental Industries use ICP-OES for quality assurance, trace metal identification, and enhancing material reliability.

3 Easy Steps to Start Testing

Case Studies

In-depth examination of genuine material testing solutions

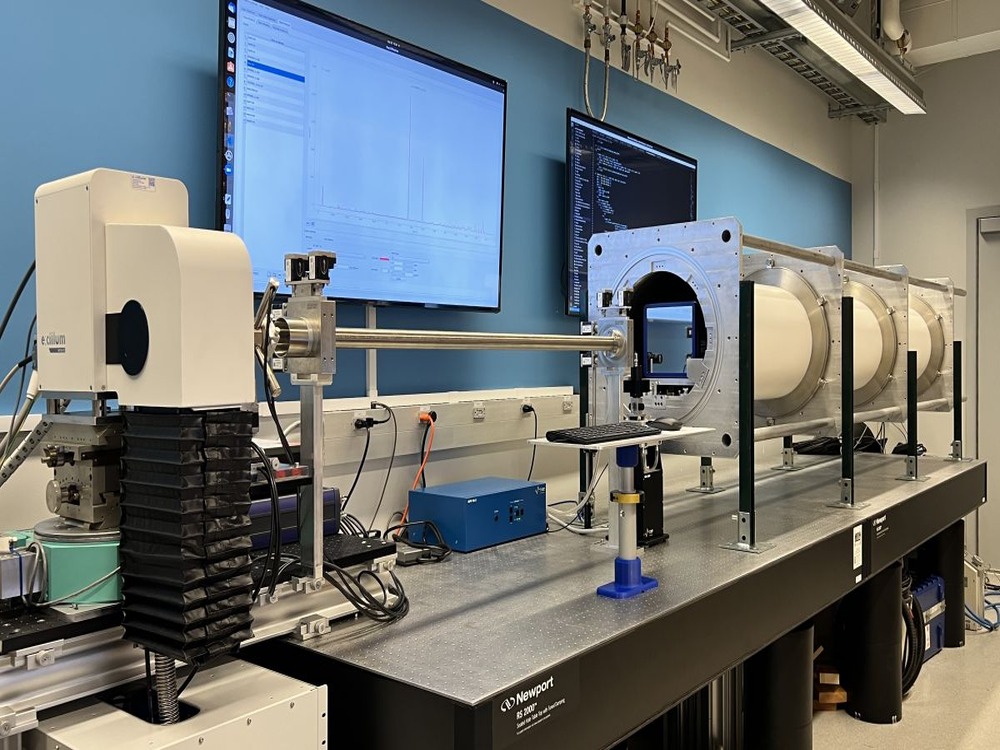

Dopant and ultra-low concentration elemental analysis using Scanning…

EELS analysis of gate and channel is performed on fin field-effect transistors (finFETs). Scanning transmission electron...

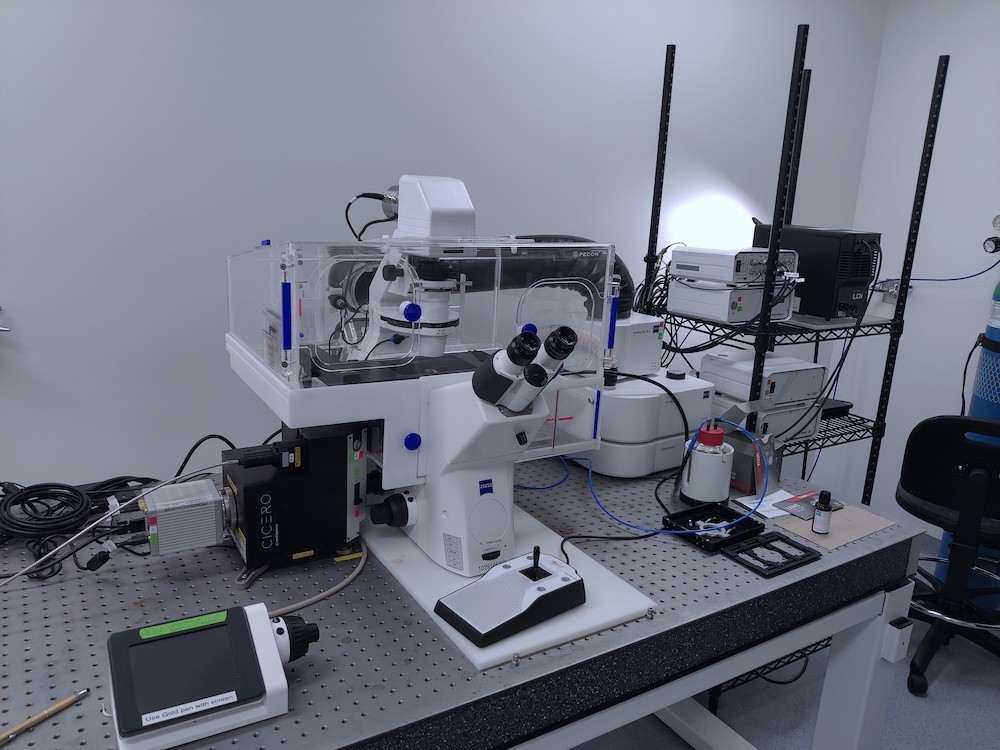

Read Case StudyAnalysis of degradation of PVC pipe using Fourier…

Introduction PVC is the polymer primarily used to make pipes for plumbing, drainage, and electrical conduits....

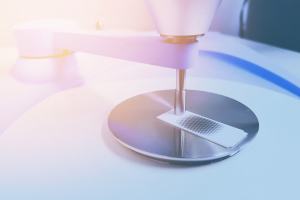

Read Case StudyNano-scale roughness measurement of Si-wafers by Atomic Force…

Nano-scale surface roughness is a critical parameter in fabricated thin-films that are used in optics, solar...

Read Case StudyTalk to Our Experts Today!

Submit your contact info and we’ll get back to you within 24 hours