Introduction of Glow Discharge Mass Spectrometry | GDMS

Glow Discharge Mass Spectrometry (GD-MS) is among the most potent solid-state analytical methods for directly determining solids’ traces, impurities, and depth profiling. Commercially available glow discharge mass spectrometers with fast and sensitive electrical ion detection enable the direct trace element determination of solid materials with good sensitivity and precision in the concentration range lower than ng g–1.6

What is Glow Discharge Mass Spectrometry?

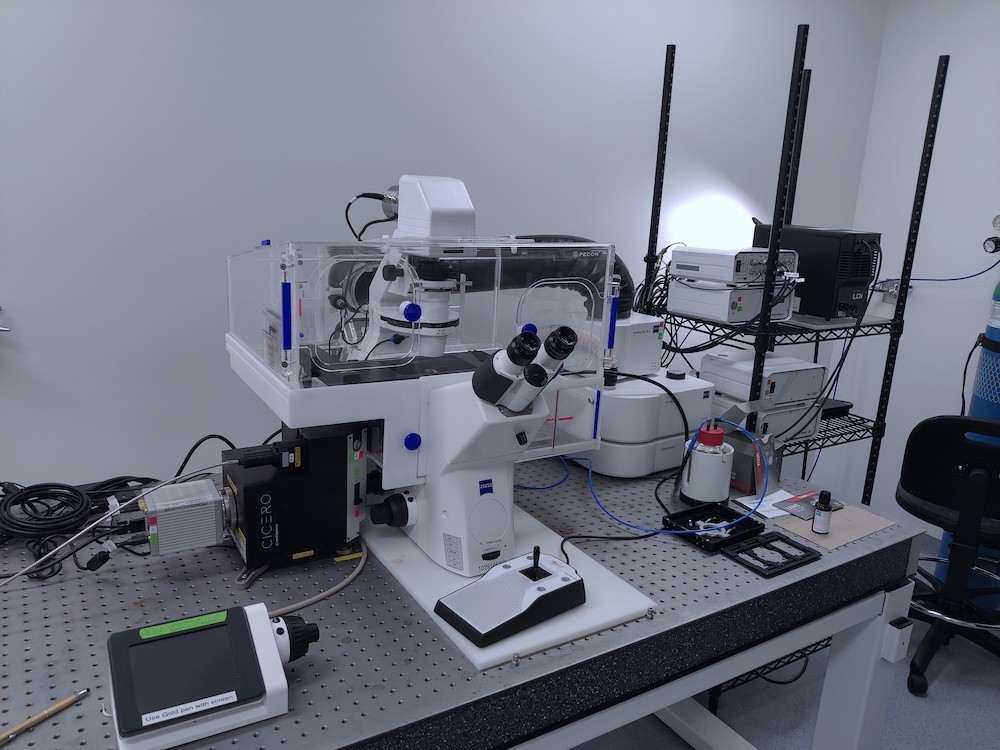

Researchers use Glow Discharge Mass Spectrometry to detect and quantify elements within solids, particularly metals and semiconductors. This susceptible method allows them to detect trace elements even in very small concentrations and analyze conductive and non-conductive materials with minimal sample preparation. As a result, they apply it extensively in areas such as metallurgy, electronics, and environmental analysis.

Scope of Glow Discharge Mass Spectrometry (GD-MS)

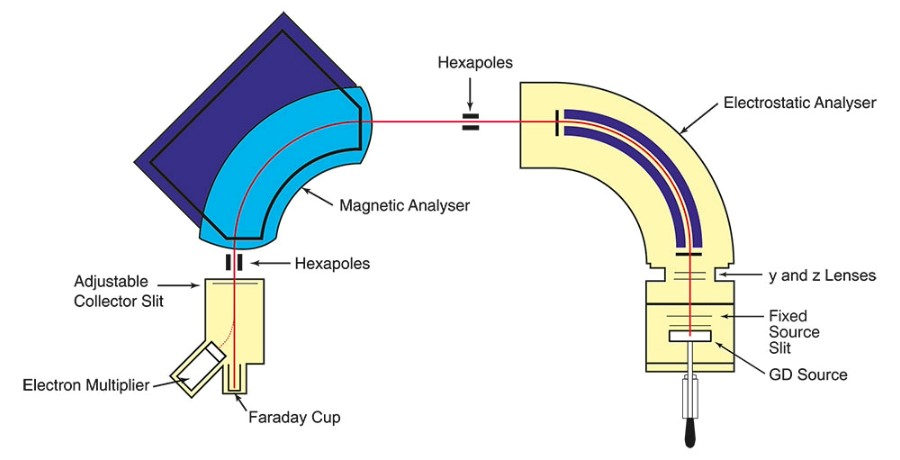

GD-MS, or Glow Discharge Mass Spectrometry, has several methods for analyzing and quantifying elements in a sample. The primary method involves using a high voltage to generate a glow discharge plasma over the sample in a low-pressure, inert gas environment, mostly argon. The energetic ions in the plasma sputter off the sample surface. Later, these atoms become further ionized inside the plasma. The ionized atoms enter a mass spectrometer, are separated by their mass-to-charge ratio, and are finally detected.

Another essential technique in GD-MS is depth profiling, where researchers gradually sputter layers from a sample to analyze its composition relative to depth. This technique is very useful in studying layered materials, coatings, or diffusion processes within solids. These techniques make GD-MS a versatile tool for a wide range of applications in the analysis of metals, semiconductors, ceramics, and even biological samples.

How Does Glow Discharge Mass Spectrometry Work?

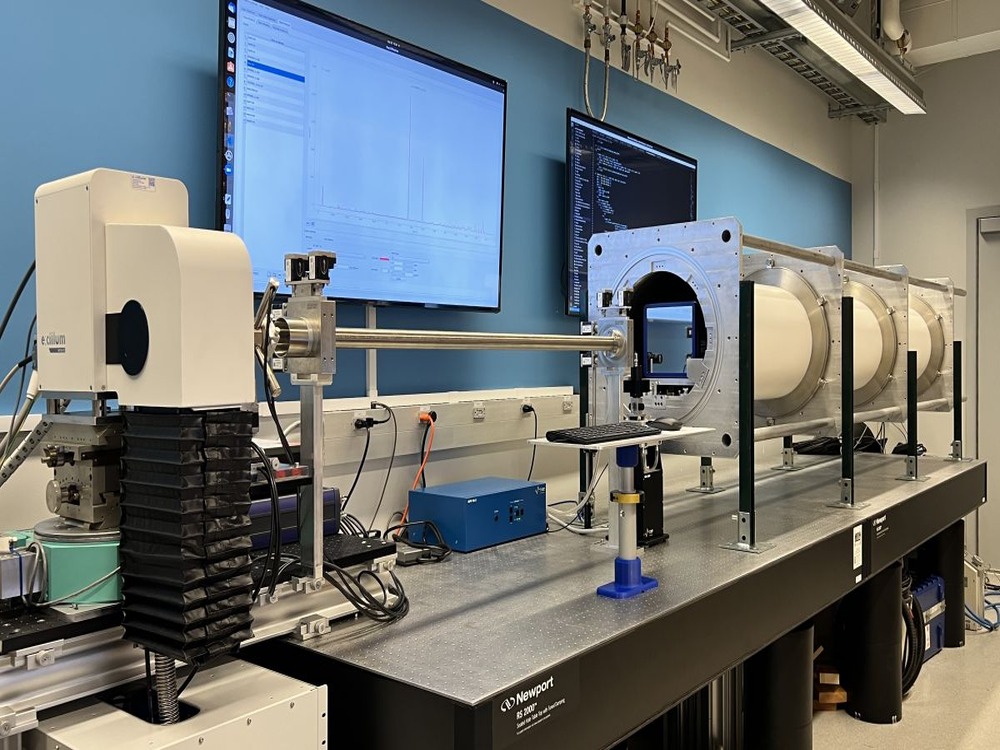

In Glow Discharge Mass Spectrometry (GD-MS), we usually generate argon plasma using a low current electrical discharge (milliamps) in a Glow Discharge Vacuum chamber filled with Argon gas. Positively charged Argon plasma ions then accelerate towards the cathode, which we form using the test sample in GDMS.

Due to bombardment by Argon plasma, researchers refer to the release of sample atoms at the cathode as ‘sputtering.’ Subsequently, the plasma ionizes the sputtered sample atoms, extracted through the anode into the mass spectrometer for detection and spectrometric analysis. Since individual compounds have their unique mass spectrum, operating the spectrometer in high-resolution mode provides a powerful technique for studying all trace and ultra-trace elemental constituents of inorganic materials.

Additionally, we can operate the Glow Discharge ion source in three different electrical modes: Direct Current (DC), Radio Frequency (RF), and pulsed Glow Discharge systems. We specifically use the radio frequency mode for non-conductive samples, whereas the pulsed mode produces higher energy plasma ions for sputtering and offers more analytical sensitivity.

GDMS has found widespread applications in analyzing trace-level elements and chemical species at surfaces and within conducting and nonconducting solids or dispersed liquids. Researchers also use it in nuclear technology to characterize atomic fuels and test materials for elemental and isotopic composition.

Pros and Cons of Glow Discharge Mass Spectrometry (GD-MS)

| Advantages | Limitations |

| Relatively free from Matrix effects and detection of species’ trace level (ppb). | Spectral interferences in the mass spectrum due to impurity gas ions and cluster ions. |

| Full element coverage (except Hydrogen). | Next, non-conductors must be powdered and mixed with conductive binders since direct RF-GD-MS equipment is not readily available. |

| The sequential operation of mass analyzers limits depth profiling applications compared to optical emission spectroscopy (OES). | The sequential operation of mass analyzers limits depth profiling applications compared to optical emission spectroscopy (OES). |

GDMS Test Conclusion

The GD-based techniques are of great use in bulk and depth profiling measurements for conductive and non-conductive samples, which have unrivaled application flexibility. One of the critical features of GD-MS is that the fast flow glow discharge mass spectrometry source uniquely offers high sensitivity with low interference levels. Moreover, a fast-flow glow discharge mass spectrometry source enables fast pumping and sample acquisition times, significantly enhancing sample throughput and laboratory productivity. GDMS has mainly been used in the characterization of nuclear concern samples. The “non-destructive” nature and fast sample preparation make the technique attractive for characterizing radioactive samples.

FAQs on Glow Discharge Mass Spectrometry | GDMS

Glow discharge mass spectrometry is an analytical technique used for the qualitative and quantitative analysis of chemical elements at concentration levels down to the ppt range.

Glow Discharge Mass Spectrometry (GDMS) is a powerful analytical method used for direct trace analysis of solids, liquids, and conducting or nonconducting materials.

Schematic of the fundamental processes in a glow discharge. Typical discharge conditions used for GDMS are about 1 kV discharge voltage, an argon gas pressure in the order of 1 torr, and a d.c. Discharge current in the mA range.

Glow discharge plasmas offer several advantages. The plasma works at sufficiently low temperatures (kinetic temperatures in the range of 100-500K) to prevent the dissociation of the molecular species.

Mass spectrometry (MS) is an analytical technique that separates ionized particles such as atoms, molecules, and clusters by using differences in the ratios of their charges to their respective masses (mass/charge; m/z).

3 Easy Steps to Start Testing

Case Studies

In-depth examination of genuine material testing solutions

Dopant and ultra-low concentration elemental analysis using Scanning…

EELS analysis of gate and channel is performed on fin field-effect transistors (finFETs). Scanning transmission electron...

Read Case StudyAnalysis of degradation of PVC pipe using Fourier…

Introduction PVC is the polymer primarily used to make pipes for plumbing, drainage, and electrical conduits....

Read Case StudyNano-scale roughness measurement of Si-wafers by Atomic Force…

Nano-scale surface roughness is a critical parameter in fabricated thin-films that are used in optics, solar...

Read Case StudyTalk to Our Experts Today!

Submit your contact info and we’ll get back to you within 24 hours