Introduction

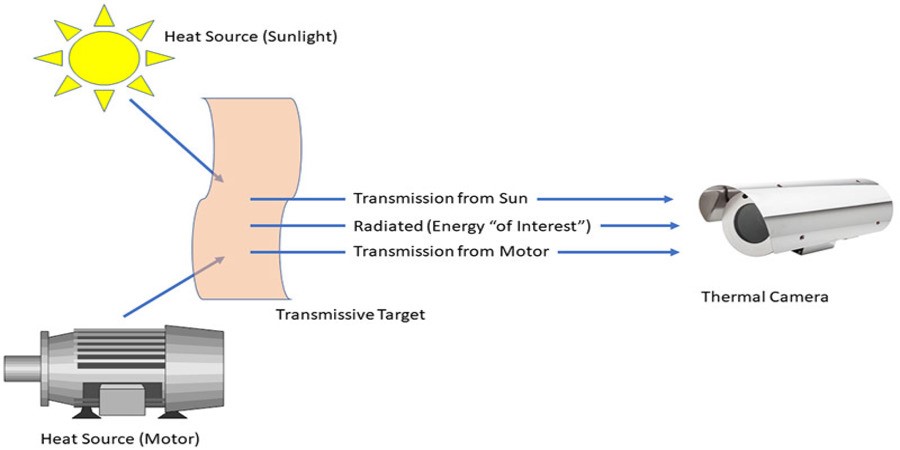

Emissivity defines an object’s ability to emit infrared energy. The energy emitted is connected with the object’s temperature. It varies from 0 to 0.95. Most organic, painted, or oxidized surfaces have emissivities close to 0.95. Most Fluke Process Instruments sensors allow for variable emissivity, so accurate readings can be made on other materials, like shiny metals.

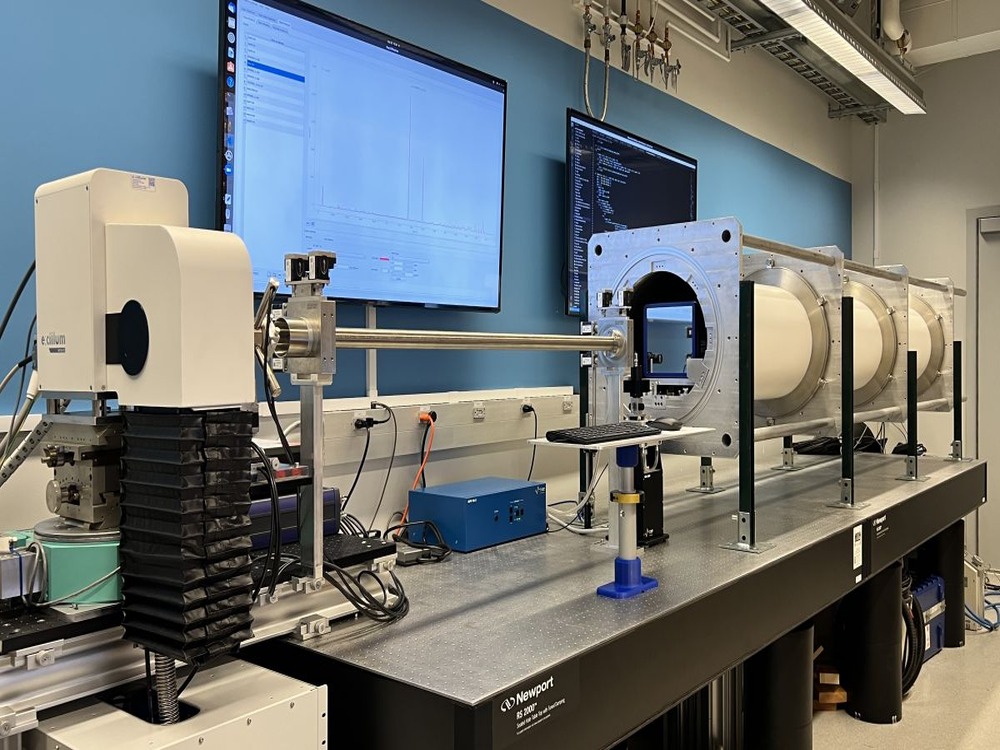

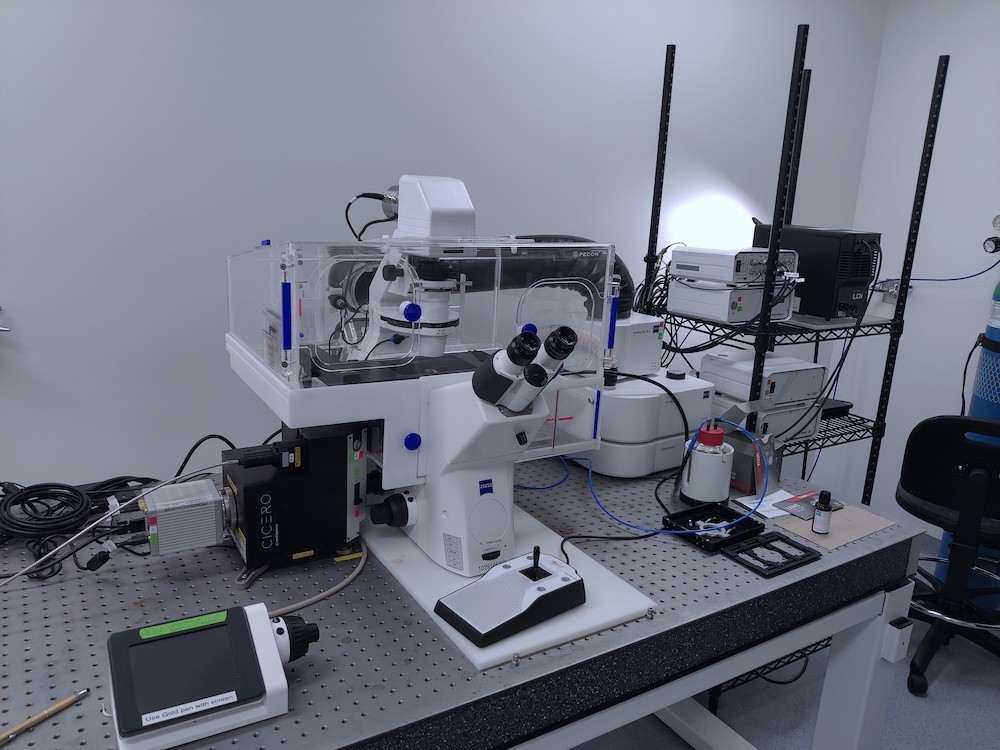

The three main methods for measuring infrared emissivity are calorimetric, radiometric, and reflection. The calorimetric method is based on heating the sample and analyzing the dissipated Stefan–Boltzmann power. Radiometry measures the surface temperature using an infrared thermometer. In reflective emissivity measurements, the intensity of the radiation reflected from a surface is measured by infrared (FTIR) and Diffuse Reflectance Infrared Fourier Transform (DRIFT) spectroscopy or by Attenuated Total Reflection (ATR).

What is Emissivity of a Material?

The emissivity of a material in thermal dynamics measures its ability to radiate thermal energy compared to a perfect black body. The Stefan Boltzmann law is computed as the ratio of thermal radiation from the surface to thermal radiation from an ideal blackbody at the same absolute temperature and wavelengths under the same viewing conditions. It is a dimensionless number, ranging from 0 (for a perfect reflector or white body) to 1 (for a black body). Its value depends on the material, the nature of the surface, and the wavelength.

Scope:

The emissivity of a material determines its capability for the emission of heat radiation compared with that of an ideal blackbody at a given temperature. It is one of the main properties in thermal analysis, describing how energy leaves a material surface by radiation. We use it explicitly in thermal imaging, energy efficiency, and temperature measurement applications. Additionally, knowing a specific material’s emissivity helps us calibrate thermal sensors accurately and optimize heat transfer in various industrial processes. In general, it affects both the design and performance of systems related to thermal radiation.

Limitations, Advantages, Uses & Application of Emissivity

The most common uses are non-contact temperature measurements using Infrared thermometers, pyrometers, and thermal imaging. Infrared thermometers are essential for the thermal engineering of furnaces, heat transfer equipment, and building and equipment insulation calculations. They have also been used to determine planetary temperatures and for space vehicle material and insulation design. Earth surface emissivity is essential for thermal remote sensing in climatology, meteorology, and oceanography.

| Limitations | Advantages | Applications |

| Interference from background radiation and transmitted radiation. | Allows non-contact temperature estimation. | Thermal engineering Remote sensing. |

| A material might have high emissivity in the infrared range but low emissivity in the visible spectrum. | Enables precise thermal modeling and design. | Semiconductors Non-destructive testing. |

| Emissivity can change with temperature for some materials. | Wavelength and temperature correlation. | Aerospace Solar flat plate collectors. |

| A material might have high emissivity in the infrared range but low emissivity in the visible spectrum. | Interference between background radiation and transmitted radiation. | A material might have high emissivity in the infrared range but low emissivity in the visible spectrum. |

Conclusion

It measures how efficiently a surface emits heat radiation compared to a perfect blackbody at the same temperature. We cast a radioactive material with thermal conductivity (k) and emissivity as a solid sphere. It is a dimensionless quantity ranging from 0 to 1.

A perfect blackbody, which absorbs all incident radiation and emits the maximum radiation at any given temperature, has the value -1. The emissivity of 0 represents an ideal reflector that does not emit any thermal radiation. It plays a crucial role in heat transfer calculations, particularly in scenarios involving radiative heat transfer, such as thermal insulation, climate studies, and the design of thermal imaging systems.

FAQs

Emissivity is defined as the ratio of the energy radiated from a material's surface to that emitted from a perfect emitter, known as a blackbody, at the same temperature and wavelength and under the same viewing conditions. It is a dimensionless number between 0 (for a perfect reflector) and 1 (for a perfect emitter).

The emissivity can be determined by one of the following methods, in order of preference: Determine the actual temperature of the material using a sensor such as an RTD, thermocouple or another suitable method.

A black body is a material that is a perfect emitter of heat energy and has an emissivity value of 1. A material with an emissivity value of 0 would be considered an ideal thermal mirror.

Emissivity (ε) is a measure of the radiated surface of the material or level of heat (scaled from 0 to 1) that is released into the surroundings.

3 Easy Steps to Start Testing

Case Studies

In-depth examination of genuine material testing solutions

Dopant and ultra-low concentration elemental analysis using Scanning…

EELS analysis of gate and channel is performed on fin field-effect transistors (finFETs). Scanning transmission electron...

Read Case StudyAnalysis of degradation of PVC pipe using Fourier…

Introduction PVC is the polymer primarily used to make pipes for plumbing, drainage, and electrical conduits....

Read Case StudyNano-scale roughness measurement of Si-wafers by Atomic Force…

Nano-scale surface roughness is a critical parameter in fabricated thin-films that are used in optics, solar...

Read Case StudyTalk to Our Experts Today!

Submit your contact info and we’ll get back to you within 24 hours