Pyrolysis Gas Chromatography/Mass Spectrometry (Pyro-GC-MS)

Pyrolysis–gas chromatography/mass spectrometry (Pyro-GC-MS) is applied to samples whose high molecular weight or lack of volatility make Gas Chromatographic separation impractical. Pyro-GC-MS utilizes controlled thermal decomposition (pyrolysis) to break-up large molecules into smaller fragments that can be separated and analyzed in a coupled Gas Chromatograph-Mass Spectrometer (GC-MS). Controlled pyrolysis is performed in a Pyrolyzer, in the presence of an inert gas.

The fragmentation of large molecules upon heating, is attributed to free radical reactions initiated by bond cleavage within the macro-molecular structure. The fragmentation pattern is characteristic for each macromolecule and reproducible under identical conditions in the Pyrolyzer. The smaller molecular fragments are capable of being processed by Gas Chromatography. Pyrolysis products are automatically introduced into the GC carrier gas stream and transferred to the GC column for analysis. The mixture of molecular fragments is separated in the GC into individual species, followed by Mass spectrometry (MS) to characterize and identify the molecular species in the fragments. This data is then processed to identify the original sample molecules.

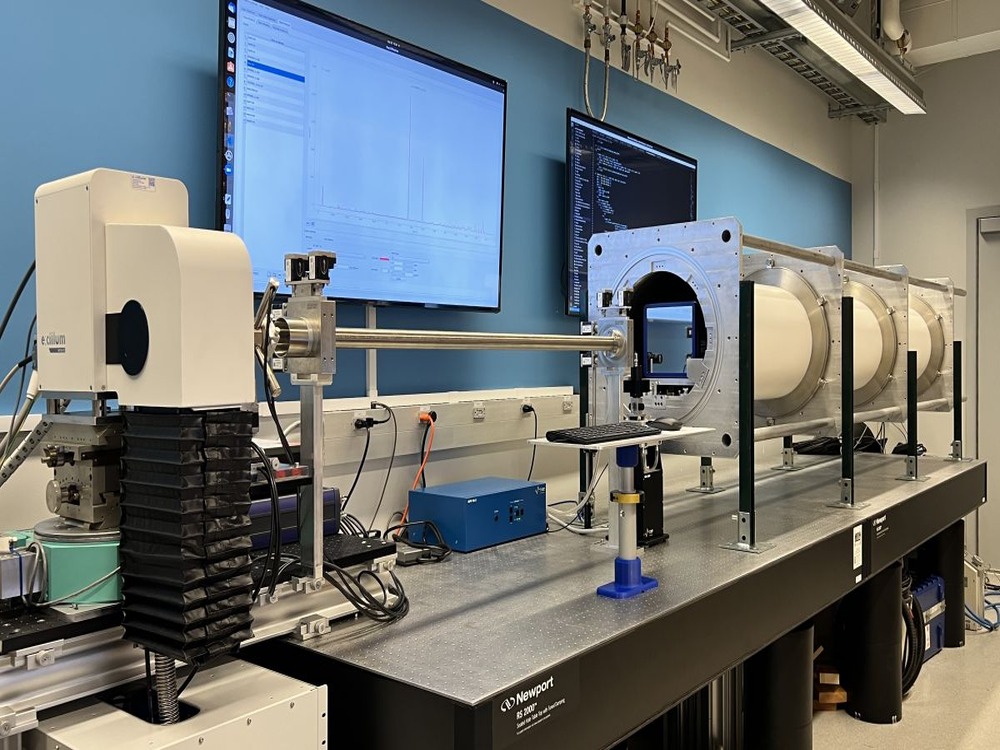

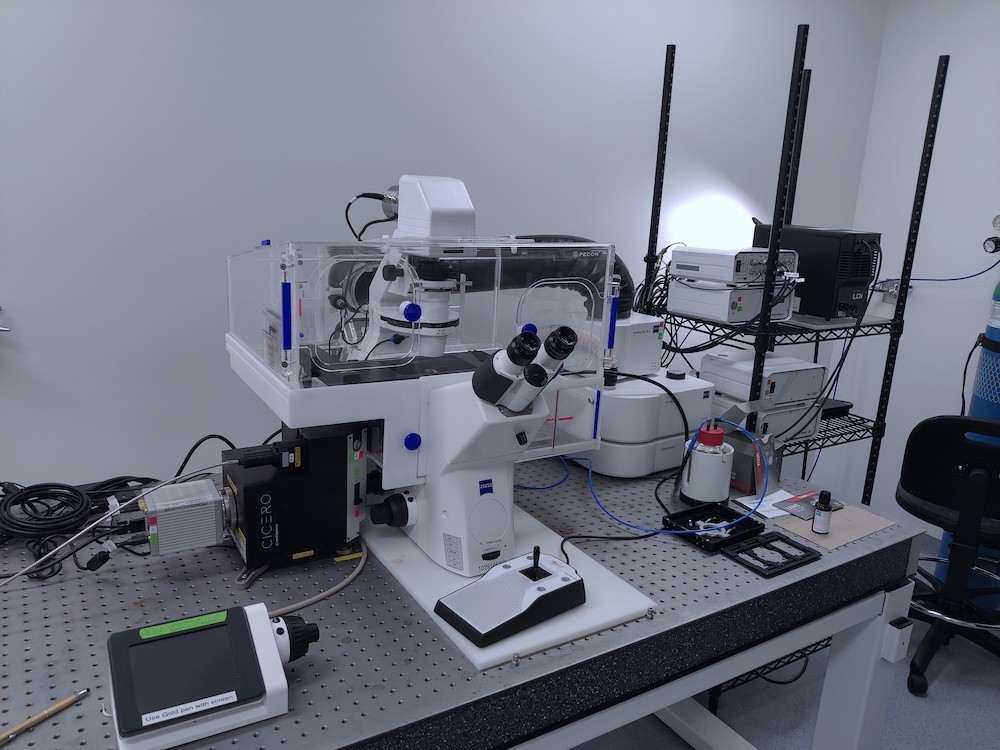

A typical Pyro-GC-MS apparatus comprises a quartz sample holder within a vertical micro-furnace, integrated with a GC-MS with necessary computerized controls and other peripherals. Inert gas connections are provided to the Pyrolyzer. Sample preparation is not needed and the quantity of sample required is very small. Sometimes, various methylating reagents are added to a sample before pyrolysis, to increase the volatility of polar fragments which tend to adsorb strongly in the GC. Pyrolyzers can be of continuous or pulse-type, depending upon the heating mechanism The temperature, heating rate and time are precisely controlled in the Pyrolyzer, for reproducibility. Some Gas Chromatographs have programmable temperature vaporizer (PTV) injectors that provide quick heating (up to 60 °C/s) and high maximum temperatures of 600-650 °C, which may be sufficient to pyrolyze many macromolecules. Pyrolysis can be single-shot or multiple-shot depending on whether the decomposition and separation is done in a single step or multiple steps.

Pyrolysis–gas chromatography/mass spectrometry finds application in research and development, quality control and investigative analysis in polymer technology, medicine, environmental pollution, biotechnology, pharmaceuticals, food, flavors and fragrances, lacquers, coatings, surfactants, textiles.

Common Uses of Pyro-GC-MS

- Analysis and identification of synthetic polymers, plastics, rubber, coatings

- Characterization of biopolymers

- Study of micro-plastics pollution in environment

- Failure analysis of polymer, elastomer and composites in automotive and chemical industries.

Advantages of Pyro-GC-MS

- Sample pre-treatment is negligible

- Due rapid decomposition under precisely controlled conditions, side reactions rarely occur.

Limitations of Pyro-GC-MS

- Sensitivity to trace molecule quantities may be affected due to insufficient pyrolysate resulting from small sample capacity.

- The molecular fragments must be suitable for GC

Industrial Applications of Pyro-GC-MS

- Polymers, plastics, Coating, lacquers, surfactants research and quality control

- Pharmaceutical research and quality control

- Automotive industry quality control

- Environmental analysis

- Flavors and fragrances

- Biotechnology

- Medical research

- Archaeological research and restoration

3 Easy Steps to Start Testing

Case Studies

In-depth examination of genuine material testing solutions

Dopant and ultra-low concentration elemental analysis using Scanning…

EELS analysis of gate and channel is performed on fin field-effect transistors (finFETs). Scanning transmission electron...

Read Case StudyAnalysis of degradation of PVC pipe using Fourier…

Introduction PVC is the polymer primarily used to make pipes for plumbing, drainage, and electrical conduits....

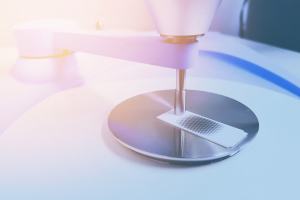

Read Case StudyNano-scale roughness measurement of Si-wafers by Atomic Force…

Nano-scale surface roughness is a critical parameter in fabricated thin-films that are used in optics, solar...

Read Case StudyTalk to Our Experts Today!

Submit your contact info and we’ll get back to you within 24 hours