Introduction

The coefficient of friction is a dimensionless variable helpful in characterizing a material’s frictional properties. COF measures the frictional forces between two surfaces when in contact.

There are two types of Coefficient of friction:

- Static Coefficient of Friction (μs): The static COF is necessary to initiate motion between the two surfaces

- Kinetic Coefficient of Friction (μk): The kinetic COF is the resistance to movement between the materials after they are set in relative motion.

ASTM D1894 is the most frequently used testing standard, while custom testing and equipment are available.COF measurement is commonly performed for plastic films, sheeting, lubricants, paper, etc.

Scope

Test data depend on the surface properties of materials, such as the sample’s surface cleanliness, roughness, surface energy, and sliding angle. This is an important parameter for product design, manufacturing, and evaluating a product’s performance.

Significance of COF in material testing:

- Quality Control

- Performance Evaluation

- Safety Assurance

- Regulatory Compliance

- Wear and Durability

Procedure of Coefficient of Friction

Testing Equipment

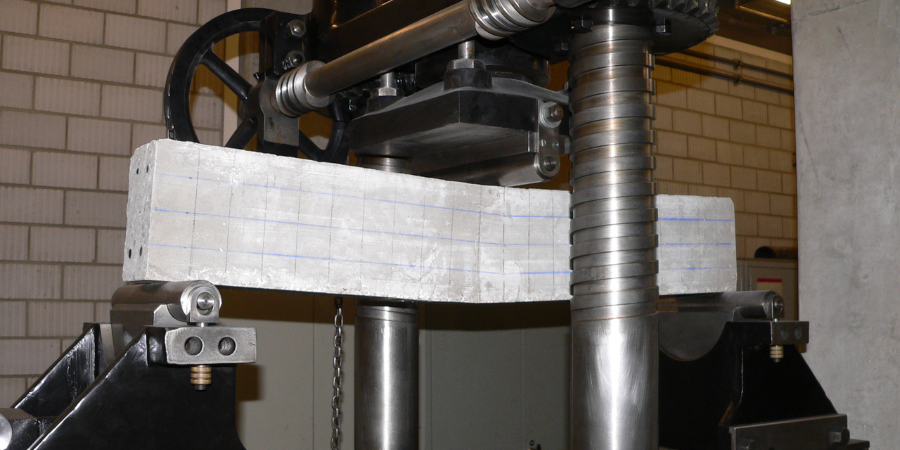

- Tribometers

- Inclined Plane Tester

- Horizontal Plane (Sled) Tester

Calculation Methods

How to find coefficient of friction? The following are some calculation methods for the coefficient of friction:

| Methods of finding coefficient of friction | The three methods to find COF areExperimental Method Using a Flat Surface:Inclined Plane Method:Using Frictional Force and Normal Force Directly |

| Methods of finding the coefficient of static friction (μs) | How do you find the coefficient of static friction? The following are some methods: Horizontal Surface Method: Calculate μs using the ratio of the force required to start motion (Fs) to the normal force (Fn) μs= FS /Fn Inclined Plane Method: Calculate μs using the tangent of the angle of inclination μs=tan(θ) |

| Methods of finding the coefficient of kinetic friction (μk) | Dynamic Friction Force (Fk): The force required to maintain constant velocity while moving the object. Normal Force (Fn): The perpendicular force exerted by the surface on the object, typically the object’s weight if on a flat surface. Coefficient of Dynamic Friction (μk): Calculated using the ratio μk=Fk / Fn |

Challenges in Calculating Coefficient of Friction

The following are some challenges in finding the COF:

| Sample Preparation | Test Conditions |

| Contaminants can change friction; thus, samples must be cleaned and handled appropriately. | Temperature and humidity fluctuations might alter COF; regulated surroundings are required. |

| Samples must be conditioned to specified temperatures and humidity conditions before testing. | Calibration and maintenance of testing devices are performed regularly to maintain accuracy and precision. |

Applications of Coefficient of Friction Testing

- Packaging Industry

- Film Handling: Assists in avoiding problems such as jamming during the manufacturing process of automobiles.

- Stacking and Stability: Assesses the performance of packages relative to each other in terms of the stability of products during transportation.

- Automotive Industry

- Tire Performance: The interaction between tires and road surfaces is something we refer to as COF, which plays a vital role in the traction and safety of the vehicle.

- Brake Systems: Brake friction materials, especially the ones used in vehicle braking systems, ought to have specific COF values.

- Flooring and Construction

- Slip Resistance: Falling and slipping are one of every building owner’s worst nightmares, which involves completing a COF test to evaluate whether the specific flooring materials are safe.

- Consumer Products

- Footwear: With the help of COF, grip and safety on various surfaces are defined.

- Appliances and Electronics: COF influences the ability to control buttons, sliders, and other controls for their usability and durable value

Conclusion

The COF is one of the most important parameters used for the characterization of materials and their interaction, as they can affect the safety, reliability, and durability of commercial goods. This makes it easier for the engineers and designers to decide the suitable materials to use and enhance product efficiency and safety in compliance with all regulations. Realizing that affects the COF and applying an appropriate methodology is critical for obtaining accurate and repeatable outcomes in numerous industries.

FAQs

The coefficient of friction (μ) is a dimensionless quantity that represents the ratio of the force of friction between two bodies to the normal force pressing them together.

There are two types of COF: Static and Kinetic (dynamic) COF.

The factors affecting COF are: Material properties, environmental conditions, and contact conditions.

The standards test methods used in calculating COF are: ASTM D1894 & ASTM C1028.

3 Easy Steps to Start Testing

Case Studies

In-depth examination of genuine material testing solutions

Dopant and ultra-low concentration elemental analysis using Scanning…

EELS analysis of gate and channel is performed on fin field-effect transistors (finFETs). Scanning transmission electron...

Read Case StudyAnalysis of degradation of PVC pipe using Fourier…

Introduction PVC is the polymer primarily used to make pipes for plumbing, drainage, and electrical conduits....

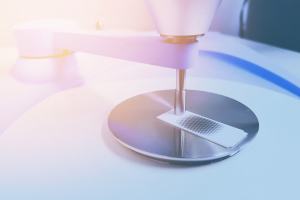

Read Case StudyNano-scale roughness measurement of Si-wafers by Atomic Force…

Nano-scale surface roughness is a critical parameter in fabricated thin-films that are used in optics, solar...

Read Case StudyTalk to Our Experts Today!

Submit your contact info and we’ll get back to you within 24 hours