ASTM D150 Test Methods for AC Loss Characteristics and Permittivity (Dielectric Constant) of Solid Electrical Insulation

The ASTM D 150 standard is an important procedure for figuring out the dielectric constant and dissipation factor of insulating materials. This test is essential for assessing a material's performance in electrical and electronic applications. It ensures that they meet the requisite standards for safety and efficiency.

TRUSTED BY

Precision-driven testing for dimensional accuracy and compliance

- Overview

- Scope, Applications, and Benefits

- Test Process

- Specifications

- Instrumentation

- Results and Deliverables

Overview

ASTM D150 is a standardized test method used to determine the dielectric constant (relative permittivity) and dissipation factor (AC electrical loss) of solid electrical insulating materials. These measures aid in assessing a material’s electrical energy storage capacity and the amount of energy lost as heat when exposed to an alternating electric field.

The technique is crucial for understanding insulation behaviour in electrical and electronic systems because it evaluates several key dielectric characteristics, including permittivity, dissipation factor, loss angle, power factor, and phase angle. ASTM D150 supports material characterisation, design validation, quality control, and the creation of high-performance insulating materials utilised in contemporary industries.

Scope, Applications, and Benefits

ASTM D150 outlines procedures for characterizing the dielectric properties of solid insulation materials under AC electrical excitation. It measures:

- Dielectric constant (relative permittivity)

- Dissipation factor (energy loss)

- Loss index and power factor

- Phase and loss angles

- Capacitance variations with frequency

This method applies to a wide range of insulating materials—such as plastics, rubber, ceramics, and laminated composites—used in electrical equipment, power systems, and high-frequency devices.

- Selection and validation of insulating materials for electrical and electronic devices

- Performance evaluation for transformers, motors, generators, and capacitors

- Testing materials for telecommunications components

- Material qualification for electric vehicles, aerospace, and renewable energy systems

- Research and development of advanced low-loss dielectric materials

- Provides accurate measurements of dielectric constant and AC loss characteristics

- Supports safe material usage at higher frequencies and voltages

- Helps manufacturers reduce power loss and improve energy efficiency

- Ensures long-term reliability of insulation systems

- Enables consistent quality control across diverse industries

Test Process

Specimen Preparation

Prepare flat, uniform insulating material samples—typically 25 mm diameter and ~3 mm thick—ensuring surfaces are clean and free of defects.

1Test Setup

Mount the specimen between electrodes and connect to an LCR meter, impedance analyzer, or ASTM D150-compliant dielectric test equipment.

2Electrical Measurement

Apply AC voltage at selected frequencies and measure capacitance, dielectric constant, and dissipation factor, ensuring no air gaps between electrodes and specimen.

3Data Recording & Evaluation

Record dielectric properties across tested frequencies (e.g., 1 kHz, 10 kHz, 100 kHz) and calculate AC loss parameters for material evaluation.

4Technical Specifications

| Parameter | Details |

|---|---|

| Test Principle | Measurement of AC permittivity and dielectric loss using precision electrical instrumentation |

| Sample Types | Solid electrical insulating materials—plastics, rubber, paper, films, laminates |

| Typical Sample Size | 25 mm diameter × ~3 mm thick |

| Equipment Used | LCR meter, precision impedance analyzer, or power factor bridge |

| Measured Outputs | Dielectric constant, dissipation factor, capacitance, power factor, loss index, phase angle |

| Frequency Range | Typically from 1 kHz to 100 kHz or as required |

| Analysis Basis | Changes in capacitance and loss characteristics under AC excitation |

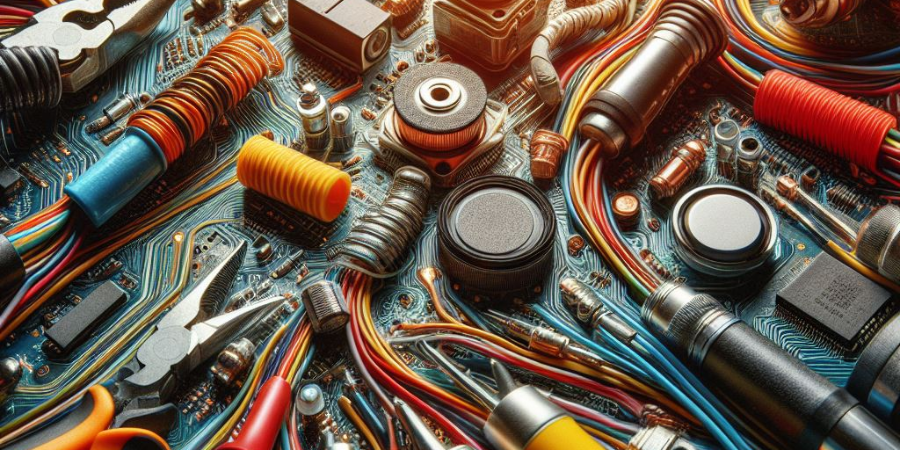

Instrumentation Used for Testing

- Precision LCR meters or impedance analyzers

- Power factor bridge instrumentation

- Electrode fixtures with controlled spacing

- Temperature- or humidity-controlled chambers (optional)

- Software for permittivity and loss calculations

- Frequency sweep systems for multi-frequency analysis

Results and Deliverables

- Dielectric constant values across the tested frequencies

- Dissipation factor and energy-loss characteristics

- Capacitance vs. frequency trends

- Loss index, power factor, and phase angle data

- Comparative performance analysis for material selection

- Suitability evaluation for electrical insulation applications

Case Studies

In-depth examination of genuine material testing solutions

Dopant and ultra-low concentration elemental analysis using Scanning…

EELS analysis of gate and channel is performed on fin field-effect transistors (finFETs). Scanning transmission electron...

Read Case StudyAnalysis of degradation of PVC pipe using Fourier…

Introduction PVC is the polymer primarily used to make pipes for plumbing, drainage, and electrical conduits....

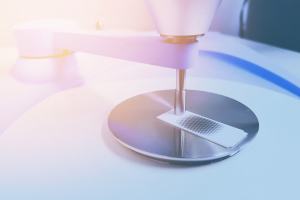

Read Case StudyNano-scale roughness measurement of Si-wafers by Atomic Force…

Nano-scale surface roughness is a critical parameter in fabricated thin-films that are used in optics, solar...

Read Case StudyFrequently Asked Questions

The ASTM D 150 standard is an essential procedure for figuring out the dielectric constant and dissipation factor.

ASTM D150 is used for measuring the AC (alternating current) dielectric properties of electrical insulating materials.

The test can be conducted at different frequencies, often between 10Hz and 2MHz—the specific frequency is determined by the customer.

The acceptable specimen thickness for ASTM D150 is typically 25 mm in diameter and 3 mm in thickness.

Request a Quote

Submit your material details and receive testing procedures, pricing, and turnaround time within 24 hours.