Temperature Testing

Temperature testing is important for examining a product’s capacity to function in harsh conditions. According to MIL-STD 810 Methods 501, 502, and 503, exposure to either a constant temperature or variable temperatures can be used for testing.

When exposed to a constant temperature, the test item is immersed in a solution until it reaches equilibrium; the test temperature must be maintained for at least two hours. To assess the test item’s susceptibility to variable temperature exposure, it must undergo at least seven cycles, equivalent to 1% of the hours of extreme temperature occurring during the most severe month in an ordinary year at the most severe site. For operational exposure testing, three cycles must be completed, with a maximum of seven cycles if repeated temperature response is challenging to obtain.

Accelerated aging testing is also used to define storage time guidelines and ascertain a product’s anticipated life cycle. Heat, humidity, vibration, and other environmental variables are used to model the long-term effects of external conditions on a product or package. Temperature testing is important for precise accelerated aging testing, making us the ideal testing partner.

Video 01: Temperature Testing

3 Easy Steps to Start Testing

Case Studies

In-depth examination of genuine material testing solutions

Dopant and ultra-low concentration elemental analysis using Scanning…

EELS analysis of gate and channel is performed on fin field-effect transistors (finFETs). Scanning transmission electron...

Read Case StudyAnalysis of degradation of PVC pipe using Fourier…

Introduction PVC is the polymer primarily used to make pipes for plumbing, drainage, and electrical conduits....

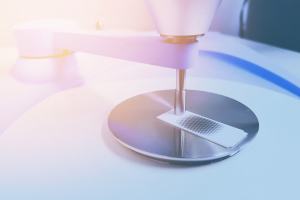

Read Case StudyNano-scale roughness measurement of Si-wafers by Atomic Force…

Nano-scale surface roughness is a critical parameter in fabricated thin-films that are used in optics, solar...

Read Case StudyTalk to Our Experts Today!

Submit your contact info and we’ll get back to you within 24 hours