What are eco-plastics?

Plastic is harmful to the environment due to its petroleum-based nature and energy consumption. Eco-plastics, such as recovered oil products and bioplastics, offer unique “green” qualities. Recycled traditional plastics are compostable, while bioplastics break down rapidly in landfills. Some eco-plastics, like PLA and PHA, are biodegradable and effective in eliminating hazardous gases. However, long-term studies are limited.

Why is there a need for eco-plastics?

Landfills in the United States process tens of billions of pounds of plastic annually. In this context, “handle” means “do nothing with” because plastic will remain unchanged for centuries. Microbes that consume other types of garbage will not touch plastic.

Due to the environmental disaster that is plastic waste in landfills, people are switching to paper grocery bags, using cardboard instead of plastic for packaged foods, and purchasing items like the Toyota Raum, a car sold exclusively in Japan and featuring “eco-plastic” components in the cabin.

It’s easy to dismiss “eco-plastic” as a contradiction in terms. It’s the next logical step toward a more sustainable way of living, though.

Eco-plastics can take many shapes and sizes. Some are merely plastics derived wholly or in part from conventional plastics that have been recycled. Plastics made from traditional petroleum sources degrade slowly over the course of centuries in landfills. The environmental value of these “eco-plastics” comes from the fact that they divert a lot of nonbiodegradable trash from landfills, even though they aren’t biodegradable any more than non recycled plastic.

Eco-friendly plastics are more commonly referred to as “bioplastics,” which are an entirely separate species. Bioplastics, which are produced from living organisms rather than fossil fuels, are expected to have fundamentally distinct characteristics. A relatively recent category of plastics, synthetic polymers, may behave differently than traditional plastics in landfills.

What are eco-plastics, how are they used, and do they help the environment? We’ll find out in this article.

To get a feel for eco-plastics, it helps to first grasp the product’s motivations. Eco-plastics, with the exception of recovered regular plastic, should primarily break down in a landfill. But the crucial question is whether or not this is even feasible.

Various Eco-Plastics

The vast majority of us have known for a long time that plastic is bad for the environment. It is petroleum-based, its production uses a lot of energy, and it takes forever to decompose in landfills. It’s tough to think of a plastic that wouldn’t make us feel bad about our purchases. It all comes down to your personal definition of “green” when deciding if eco-plastics are up to snuff.

There are several varieties of eco-plastics available, including those made from recovered oil products, plastics made from plants (bioplastics), and others. Each one has unique “green” qualities.

The amount of “virgin” (non recycled) traditional plastic that makes up recycled traditional plastic varies. The virgin plastic that would otherwise go to waste in landfills is instead recycled into eco-friendly outdoor furniture. However, this kind is not much more compostable than the conventional variety.

It is expected that bioplastic, which is derived from plants, will break down rapidly in landfills and, in some circumstances, compost piles. Polylactide (PLA) plastic is the most common type, and it is derived from starch (often maize starch). Disposable cups and food-service trays made from PLA are commonplace. Starch is also used to make polyhydroxyalkanoate (PHA) plastic, which can be found in containers like those used to store cosmetics. Cellulose, the primary component in plant tissues, provides the basis for cellulose-based polymers. Bioplastics such as those derived from lactic acid or soy protein are also available.

Last but not least, the “miscellaneous” category includes a number of cutting-edge plastic developments. ECM Biofilms has created a new technology that makes it possible to produce conventional plastics with the aid of microbe-attracting pellets. Novomer’s proposed biodegradable plastic would have the “green” benefits of being both biodegradable and effective at eliminating hazardous gases from the air (by reacting carbon dioxide and carbon monoxide with liquid metal).

All of these eco-plastics have advantages over conventional plastics from an environmental standpoint, but the question boils down to whether or not these advantages hold up in actual use. This type of plastic is supposed to biodegrade. However, long-term studies are rare because they are still relatively novel, at least in the context of the industrial sector.

Will there be green plastic?

Bioplastics, and more specifically PLA, the most prevalent starch-based variety, have been the focus of the vast majority of studies on the biodegradability of eco-plastics to date. What we do know is this:

While PLA is biodegradable, it doesn’t break down very quickly. The real-time range for landfill conditions is unknown to us. While decomposition after disposal is expected, it is unclear how quickly or how long it will take to occur. Composting can take anywhere from three months to a year, depending on the conditions, according to some studies .However, some studies have revealed that composting can’t happen at all in home compost settings, and that only commercial setups can break the item down.

We do know that it will take up the same volume as petroleum-based plastic until it decomposes. The material volume of most bioplastic containers is at least equal to that of their conventional plastic counterparts.

A major problem with eco-plastics is the amount of energy required to produce them, which is on par with the garbage they produce and their tendency to biodegrade. Is there a difference in the amount of energy required to produce petroleum-based and “green” plastic containers? The verdict on that is still out for now. Some have argued that it utilizes roughly the same amount, since it requires just as much energy to shape starch-based material into cup form as it does fossil fuel-based material. One thing to keep in mind is that eco-plastic producers typically use low- or no-energy production methods because they are targeting the “green” market. For example, Ingeo, a bioplastics manufacturer, has implemented new production methods that cut the company’s GHG emissions by 60% and its energy consumption by 30%. The production of Ingeo bioplastic, the business claims, now generates 77% less carbon dioxide than conventional petroleum-based plastic.

The use of land is a major problem for the environment when it comes to bioplastics. Farmland is diverted from food and fuel crop production to fuel crops including corn, sugarcane, and beets. However, it may be worthwhile if we absolutely must have our plastics: ConAgra believes it saved half a million pounds of CO2 when it moved from petroleum-based plastic to PLA plastic for the shrink wraps on some of its products, such as Parkay and Fleishmann’s margarine. Imagine if the tubs themselves were also made from bioplastics.

3 Easy Steps to Start Testing

Case Studies

In-depth examination of genuine material testing solutions

Dopant and ultra-low concentration elemental analysis using Scanning…

EELS analysis of gate and channel is performed on fin field-effect transistors (finFETs). Scanning transmission electron...

Read Case StudyAnalysis of degradation of PVC pipe using Fourier…

Introduction PVC is the polymer primarily used to make pipes for plumbing, drainage, and electrical conduits....

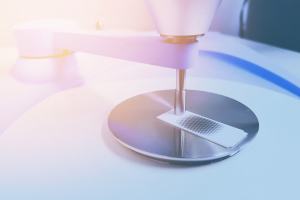

Read Case StudyNano-scale roughness measurement of Si-wafers by Atomic Force…

Nano-scale surface roughness is a critical parameter in fabricated thin-films that are used in optics, solar...

Read Case StudyTalk to Our Experts Today!

Submit your contact info and we’ll get back to you within 24 hours