X Ray Diffraction XRD Introduction

X-ray diffraction analysis (XRD) is a non-destructive technique to study all types of material. It’s also a characterization technique used for crystalline materials. In many industries, the materials researcher has many analytical questions about the material’s chemical composition and crystalline constitution. The XRD analysis is the only method that gives precise information about the chemical composition, crystal structure, crystal orientation, crystallite size, lattice strain, preferred orientation, and layer thickness.

Principle of XRD Analysis

In a diffractometer, incident X-rays scatter (diffract) at specific angles from the sample’s lattice planes, producing diffraction peaks characteristic of a simple crystal structure. The electron is the scatterer in this event, referred to as elastic scattering. The diffraction patterns give information like phase, atomic plane spacing (d-spacing), crystal structure, preferred orientation (texture), average grain size, crystallinity, strain, crystallite size, crystal defects, etc.

A regular array of spherical waves results from a regular array of scatterers. These waves interfere destructively in the vast majority of directions, but according to Bragg’s law, they add constructively in the following few directions:

2dsinθ = nλ

Where,

n is an integer,

θ is the incident angle,

d is the distance between diffracting planes and

λ is the wavelength of the beam.

What are the Types of XRD?

Researchers can tailor XRD techniques to various types of analysis depending on the material under investigation and the specific information they need to obtain. The main types of XRD techniques are as follows.

- Powder X-ray Diffraction Analysis (PXRD)

In PXRD, a fine powder is irradiated with X-rays. The random orientation of crystallites in the powder gives a diffraction pattern representative of the crystal structure.

- Single Crystal X-ray Diffraction Analysis (SC-XRD)

In SC-XRD, researchers use a single crystal instead of powder. They direct X-rays onto the single crystal, and the resulting diffraction pattern helps determine the exact 3D atomic structure of the crystal.

- High-resolution X-ray diffraction Analysis (HRXRD)

HRXRD is among the latest techniques for detailed structure analysis of epitaxial layers and thin films. It provides a high angular resolution for studying lattice strain, dislocations, and interface quality in thin films.

- Grazing Incidence XRD Analysis (GI-XRD)

Grazing incidence XRD (GI-XRD) is Suitable for polycrystalline, substrate-deposited, or ion-irradiated thin films, where traditional XRD might penetrate too deep into the substrate. Micro XRD is Widely used for micron to nm scale crystallographic exploration of samples.

Scope of XRD Analysis

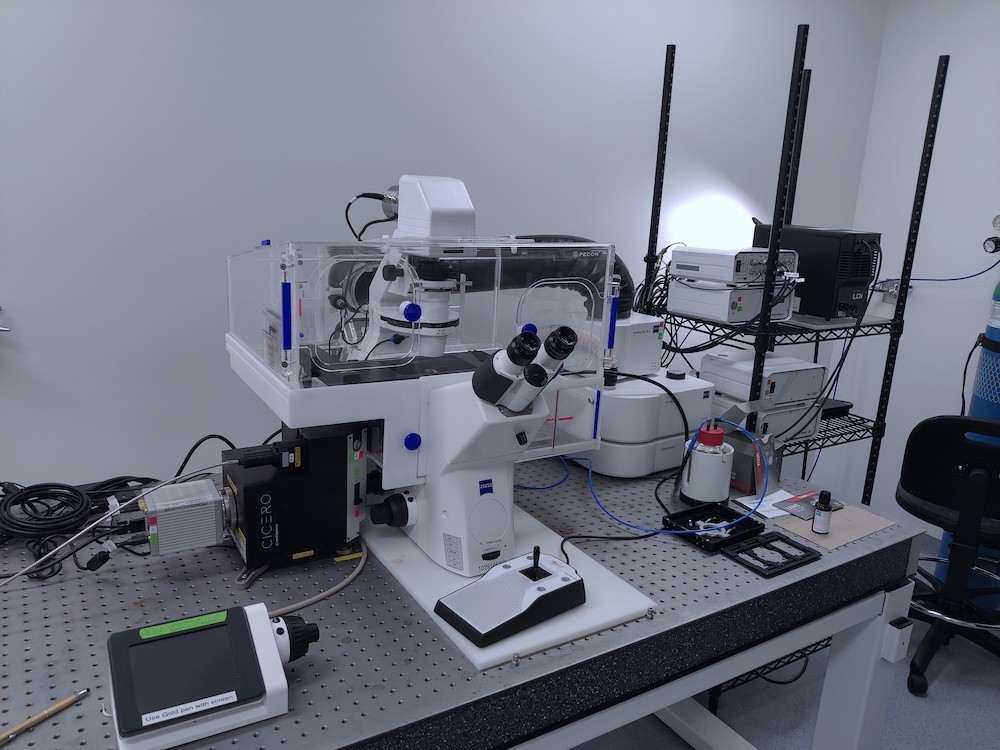

One of the main applications of XRD analysis is identifying materials based on their diffraction pattern. In addition to phase identification, residual stress analysis by X – Ray Diffraction is common. Researchers extensively use it for identification of clay minerals by x ray diffraction analysis, identifying new and unknown materials, characterizing substrates in integrated circuit production, protein crystallography, solid-state drug analysis, and more. Various XRD configurations are available to suit the type of application.

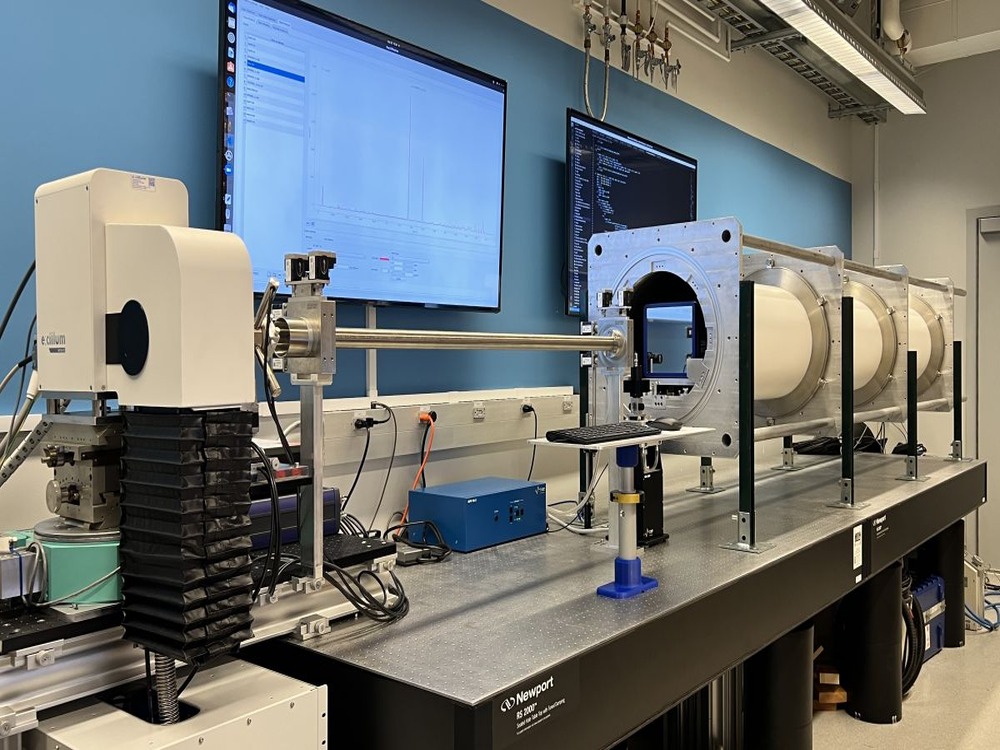

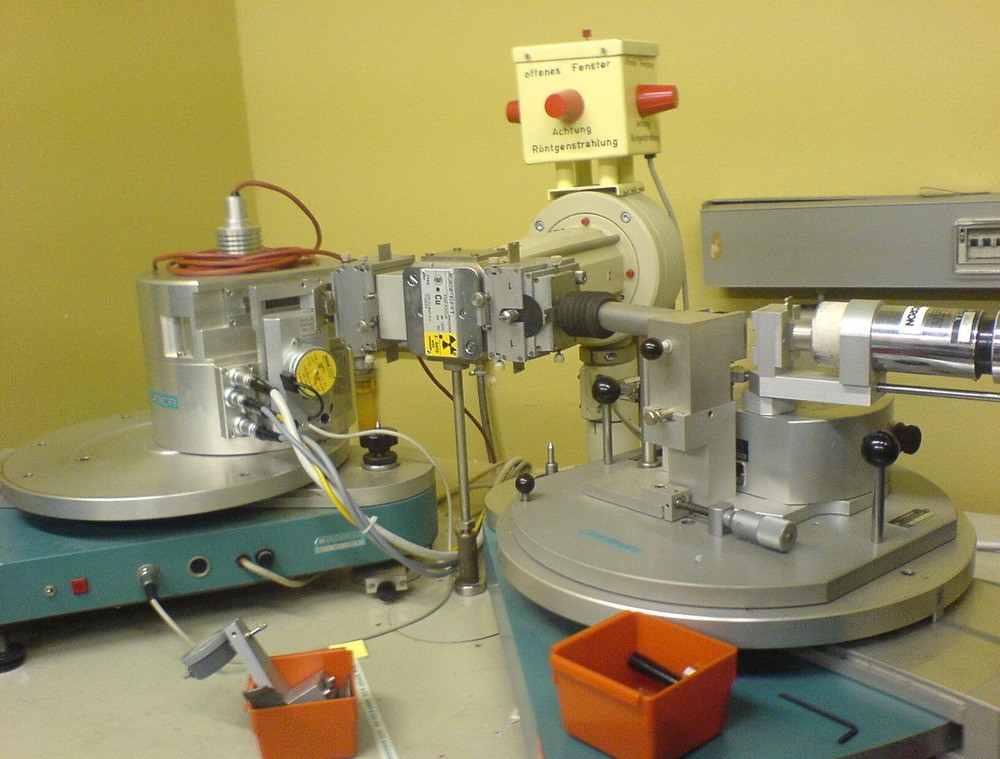

Instrumentation of XRD (X Ray Diffraction )

An X-ray instrument contains three main items: an X-ray source, a sample holder, and an XRD detector.

- The X-ray source or tube is usually the source of X-rays. It is a sealed X-ray tube made mostly of copper, molybdenum, or cobalt. Synchrotron sources produce intense and tunable X-rays, allowing researchers to use them in advanced applications.

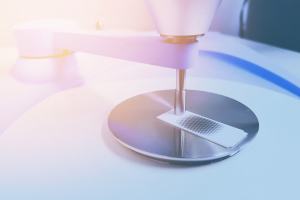

- The sample is either finely powdered or thin film and placed in a sample holder. It may also rotate during the pattern measurement. The goniometer is a precise mechanical device that positions and moves the sample/detector to measure angles accurately.

- The detector measures the intensity of diffracted X-rays from different angles. Researchers process the detector signal and represent it as a diffraction pattern, which they then analyze for its crystallographic structure. Some commonly used detectors are scintillation counters, proportional counters, and solid-state detectors such as CCD (Charge-Coupled Device) or CMOS sensors.

Pros and Cons of XRD Analysis

The pros and cons of XRD analysis are as follows:

| Limitations | Advancements |

| It is hard to characterize mixed, non-homogenous, multi-phase samples and non-isometric crystals. | Acceptable thin-film size range: 10um to 2nm. |

| High-angle reflections can result in peak overlay. | XRD is a non-destructive, high-sensitive, and reliable test. |

| No depth profile information. | The analysis has fast run times (~20 minutes). |

| Minimum spot size of ~ 20µm. | In comparison with electron microscopy, it can’t create real-space images of materials because suitable lenses don’t exist. |

Compared with electron microscopy, it can’t create real-space images of materials because suitable lenses don’t exist. | Databases with standard diffraction patterns are available for thousands of materials. |

Conclusion

The importance of X-ray diffraction (XRD) in determining crystalline materials with high applicability to a scope of influence and many essential fields is very high. In material science and metallurgy, it is used for phase identification and crystal structure. In the pharmaceutical industry, the technique is popular because it determines the purity of drug compounds. Geologists and miners utilize XRD for mineral identification and in checking ore quality. In the semiconductor industry, high-resolution XRD studies thin films and epitaxial layers. It extends its application to material studies such as catalysts, corrosion products, and environmental samples and is important in both material development and environmental monitoring.

FAQs on XRD (X Ray Diffraction )

X-ray diffraction (XRD) X-ray diffraction is a technique to characterize crystalline materials.

X-ray diffractometers are the main component of XRD. An X-ray instrument contains three main items: an X-ray source, a sample holder, and an XRD detector.

XRD uses X-rays to determine a molecule's geometry or shape. Its techniques are based on the elastic scattering of X-rays from structures with long-range order.

Ideally, 2 g is required, but depending on the analysis required, this can be as little as 20 mg.

3 Easy Steps to Start Testing

Case Studies

In-depth examination of genuine material testing solutions

Dopant and ultra-low concentration elemental analysis using Scanning…

EELS analysis of gate and channel is performed on fin field-effect transistors (finFETs). Scanning transmission electron...

Read Case StudyAnalysis of degradation of PVC pipe using Fourier…

Introduction PVC is the polymer primarily used to make pipes for plumbing, drainage, and electrical conduits....

Read Case StudyNano-scale roughness measurement of Si-wafers by Atomic Force…

Nano-scale surface roughness is a critical parameter in fabricated thin-films that are used in optics, solar...

Read Case StudyTalk to Our Experts Today!

Submit your contact info and we’ll get back to you within 24 hours