High Res XPS Introduction

High res XPS (High-resolution X-ray Photoelectron Spectroscopy) is a photoelectron spectroscopy (PES) type that uses a monochromator instead of a standard X-ray source.

Photoelectron spectroscopies follow the photoelectric effect. Electrons are released when a material is exposed to electromagnetic radiation, such as light, known as the photoelectric effect. The photoelectric effect draws properties of atoms, molecules, and solids.

High-resolution X-ray Photoelectron Spectroscopy (HR-XPS)

What is High Res XPS?

In high resolution x-ray photoelectron spectroscopy, researchers bombard a sample with high-energy radiation (X-rays), knocking electrons out from the material’s surface. The sample’s ejected electrons then proceed to an energy analyzer, where researchers note their kinetic energies, followed by a detector that counts the number of photoelectrons at various kinetic energies.

Plots of Photoelectron Count vs. Binding Energy

Plots of photoelectron count vs. binding energy represent the data from PES experiments. These plots are called PES spectrums. PES spectra infer elemental composition, chemical state, and overall electronic structure. When the energy resolution is low, the elements present are described qualitatively and quantitatively, whereas when the resolution is excellent, the chemical state and bonding of the elements are described.

Scope of High Res XPS:

High-resolution X-ray Photoelectron Spectroscopy represents the detailed analysis of surface chemistry and, therefore, forms an efficient tool in material science and nanotechnology, studying the elemental composition, chemical states, and electronic structure of materials at an atomic level. Its application spans a wide range from material science and nanotechnology to semiconductor studies, where precise surface characterization plays an important role. Particularly, the analysis of thin films, coatings, and interfaces by HR-XPS represents excellent value for investigating the oxidation state, chemical bonding, and contamination layers. Further, it finds extensive applications in catalysis research, corrosion studies, and advanced material development because understanding surface interactions and modifications can improve performance and durability.

Sample Analysis of High Res XPS

High-resolution X-ray photoelectron spectroscopy (HR-XPS) is a crucial analysis done on samples in research to achieve proper and accurate surface characterization. The process is an overview below:

- Preparation of the Sample

The sample’s surface should be clean and free of dust, oils, and oxidation layers, as these interfere with photoelectron signals and affect the analysis’s accuracy.

The sample is generally small, a few millimeters, and should be flat to ensure uniform exposure to the X-ray beam.

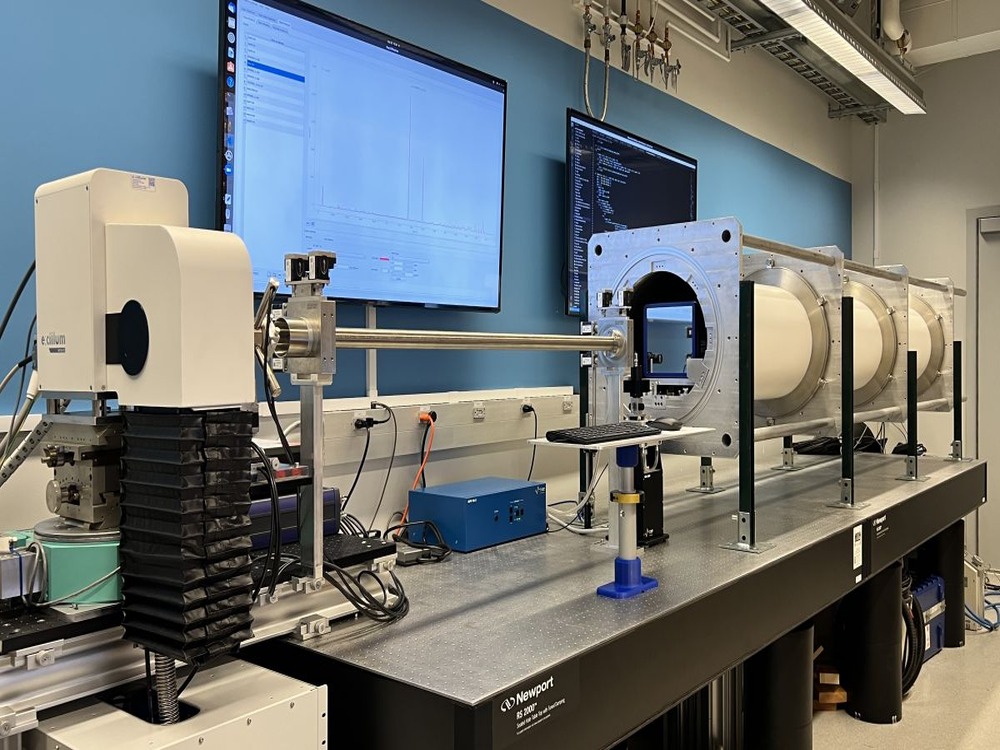

- Introduction to the Vacuum Chamber

The sample enters the HR-XPS instrument’s ultra-high vacuum (UHV) chamber. The vacuum is required to prevent air molecules from interfering and to let the emitted photoelectrons reach the detector without scattering them.

- X-ray Excitation

Researchers irradiate the sample with high-energy X-rays, usually generated by a monochromatic X-ray source. The energy of the incoming X-rays is sufficient to eject core-level electrons from the surface atoms.

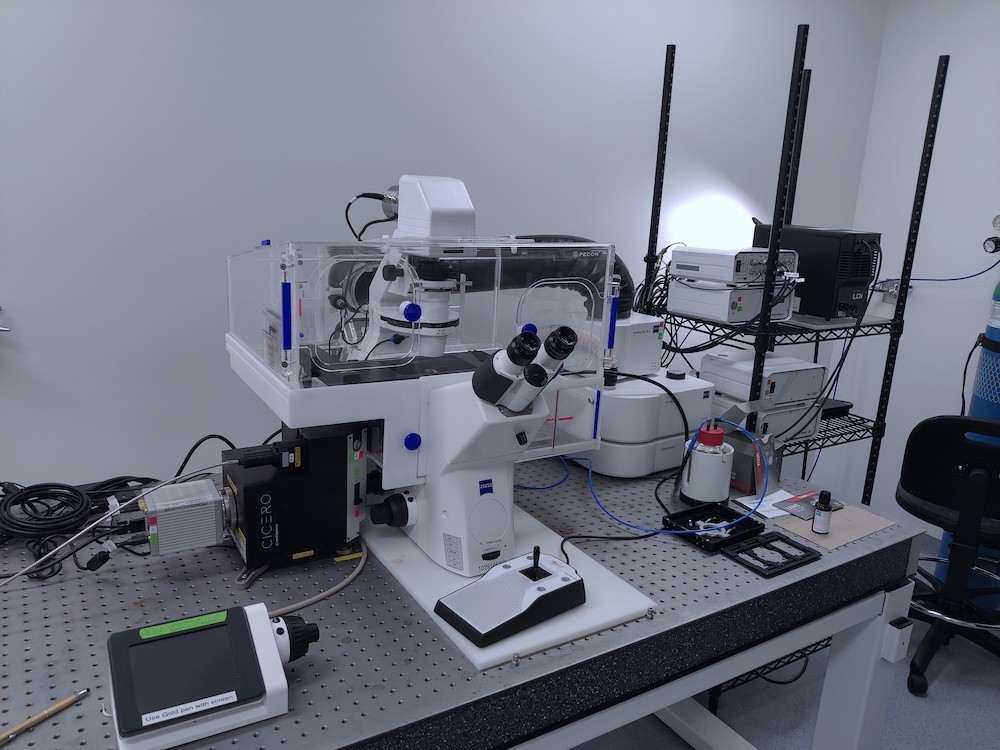

- Detection of the Photoelectron

The ejected photoelectrons are collected within an electron energy analyzer, which measures the kinetic energy of the ejected electrons. From the kinetic energy of the electrons, HR-XPS can then provide information about the binding energy of the electrons in the material; this is directly related to the chemical state of the elements being present.

- High-Resolution Analysis

HR-XPS allows for high-resolution analysis and can differentiate even slight differences in the binding energy. This becomes important in determining varied chemical states of a specific element, like chemical environments or oxidation states.

Advantages, Disadvantages, & Uses of High Res XPS

High-resolution soft x-ray photoelectron spectroscopy of liquid water has several advantages, disadvantages, and uses. Some of the critical features are tabulated below:

| Advantages | Disadvantages | Uses |

| Higher chemical selectivity | HR-XPS requires high vacuum conditions. | Inorganic substances, metal alloys, semiconductors, polymers, paints, papers, biomaterials, viscous oils, glues, and many other materials are all analyzed using HR-XPS. |

| Lower spectral background | Samples must be compatible with a high vacuum environment. | It utilized in-depth profiling when combined with ion-beam etching. |

| Fewer unwanted X-rays | The sample’s length, width, and height should be less than 25 mm and less than 12 mm, respectively. | In-line profiling of the elemental composition throughout the surface. |

| Lower bremsstrahlung and thermal radiation from the X-ray source, reducing X-ray source-induced damage. | Surface Sensitivity and Limited Depth Penetration | Chemical State Identification |

High Res XPS Test Conclusion

High Res XPS is among the most important analytical techniques today for understanding surface chemistry in materials. The depth of information it can deliver regarding elemental composition, chemical states, and surface interactions on a nanometric scale. It has made it an absolute necessity that cuts through into many fields of study, such as materials science, semiconductor research, catalysis, and environmental science. It is a surface-sensitive technique requiring much care during sample preparation. Still, such depth of analysis and precision are invaluable in pushing our understanding of material surfaces and interfaces forward. Finally, HR-XPS will remain cornerstones in exploring and optimizing surface-related phenomena as industries forge ahead with innovations that drive material performance to the extreme.

Infinita Lab offers comprehensive High Res XPS Testing Services, ensuring precise and reliable results. With a network of accredited material testing laboratories across the USA, Infinita Lab provides nationwide coverage, including 16 office locations, doorstep sample pickup, and expert consultancy for detailed report analysis. Our extensive catalog includes over 2000 material science tests. Our services help industries such as semiconductor, aerospace, medical devices, renewable energy. Trust Infinita Lab for your material testing needs. Visit our website to learn more and schedule your testing services today.

FAQs on High Res XPS

High Res XPS is an advanced analytical tool that can determine the elemental composition, identify the chemical states, and probe the electronic structure at the nanoscale.

Significant differences exist in resolution and sensitivity between high-resolution XPS and conventional XPS. HR-XPS produces higher energy resolution, allowing it to pick up minimal differences in the chemical state and provide more accurate descriptions of complicated materials.

High-res XPS allows the investigation of an extensive range of materials, like metals, semiconductors, polymers, ceramics, thin films, and nanomaterials.

One of HR-XPS's main limitations is its extreme surface sensitivity, which typically examines only the top few nanometers of a material.

HR-XPS is used in many applications that involve catalysis, semiconductor research, battery development, corrosion studies, and nanotechnology.

3 Easy Steps to Start Testing

Case Studies

In-depth examination of genuine material testing solutions

Dopant and ultra-low concentration elemental analysis using Scanning…

EELS analysis of gate and channel is performed on fin field-effect transistors (finFETs). Scanning transmission electron...

Read Case StudyAnalysis of degradation of PVC pipe using Fourier…

Introduction PVC is the polymer primarily used to make pipes for plumbing, drainage, and electrical conduits....

Read Case StudyNano-scale roughness measurement of Si-wafers by Atomic Force…

Nano-scale surface roughness is a critical parameter in fabricated thin-films that are used in optics, solar...

Read Case StudyTalk to Our Experts Today!

Submit your contact info and we’ll get back to you within 24 hours