What is EBSD (Electron Backscatter Diffraction)?

EBSD (Electron Backscatter Diffraction) is a potent technique used to examine the crystalline phases of solid samples down to sub-micron levels of detail. Commonly, variations in the microstructure of materials can have as much or more impact on the properties of interest than the bulk sample’s chemistry, even though chemical analysis to determine the gross composition is frequently helpful in materials science and other related applications.

The orientation and association of grains in alloys and metal parts often significantly affect strength, magnetic properties, and hardness. Ceramics also differ considerably due to different grain sizes, sintering effects, and crystallinity, which can result in very different properties. This makes piezoelectric or magnetically active ceramic compounds quite different. Even petrographic analyses, crystalline polymers, and composites all better understand the microscale crystalline properties of the bulk material.

Electron Backscatter Diffraction (EBSD) Test Scope:

EBSD stands for Electron Backscatter Diffraction, an integrated part of certain SEMs to assess the crystallography of any material at the micro-level. More specifically, it offers users in-depth crystallography orientation maps within single grains of a polycrystalline material, allowing them to plot and measure grain structure and boundaries in relative terms. On the other hand, EBSD is a phase identification technology that compares the diffraction pattern to know the phase databases. It has made EBSD a handy tool in various disciplines, such as material science, geology, and metallurgy. It also supports texture analysis to gain some understanding and, hence, the prediction of material properties like strength, ductility, and corrosion, which depend on the grains’ preferred orientation. Researchers can extend EBSD to strain studies, where even slight distortions in the diffraction patterns reveal small changes in the internal stresses within a material.

Procedure of Electron Backscatter Diffraction (EBSD)

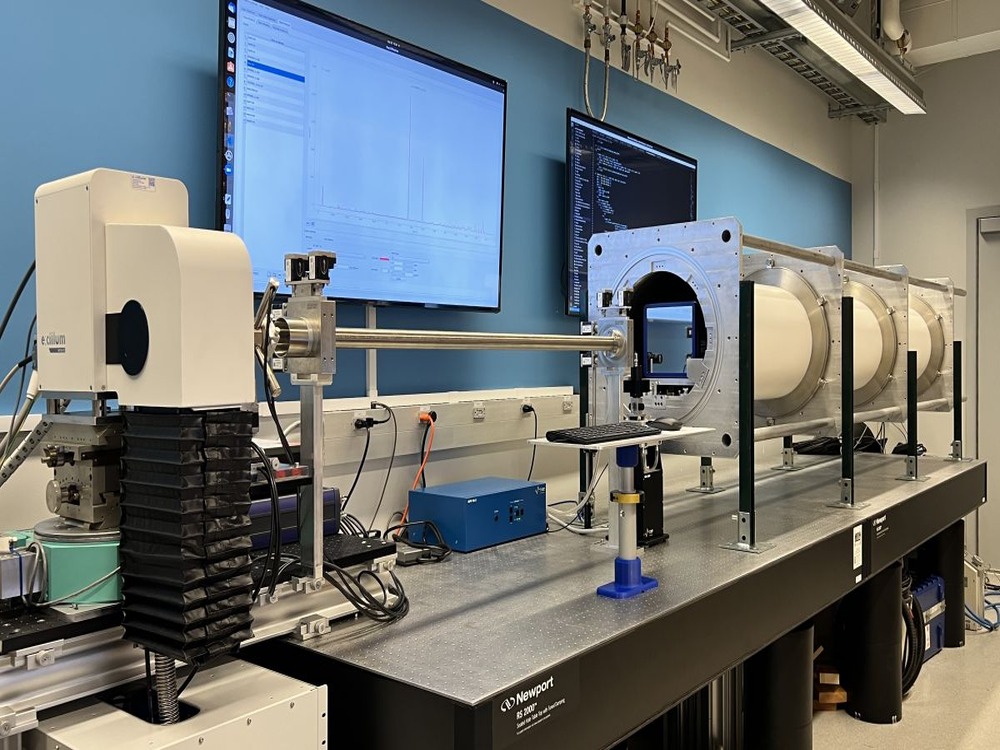

EBSD demands that researchers prepare samples through cautious procedures, polishing the sample’s surface to achieve very high smoothness and flatness. They usually perform this mechanically, using colloidal silica for finer polishing to avoid surface damage. After polishing, they meticulously clean the sample to remove any debris or contamination that might interfere with the diffraction patterns. Once prepared, they mount the sample in the scanning electron microscope with the surface of interest facing the electron beam. They then tilt the sample to a steep angle, usually about 70°, to the electron beam to obtain the best quality of emitted backscattered electrons. Set up SEM to produce a finely focused electron beam. Researchers generally use an accelerating voltage between 15 and 30 kV. They carefully set up the EBSD to catch the backscattered electrons while still in a diffraction pattern, allowing further analysis of the material’s crystallographic orientation and phase information.

Electron Backscatter Diffraction (EBSD) Sample Analysis

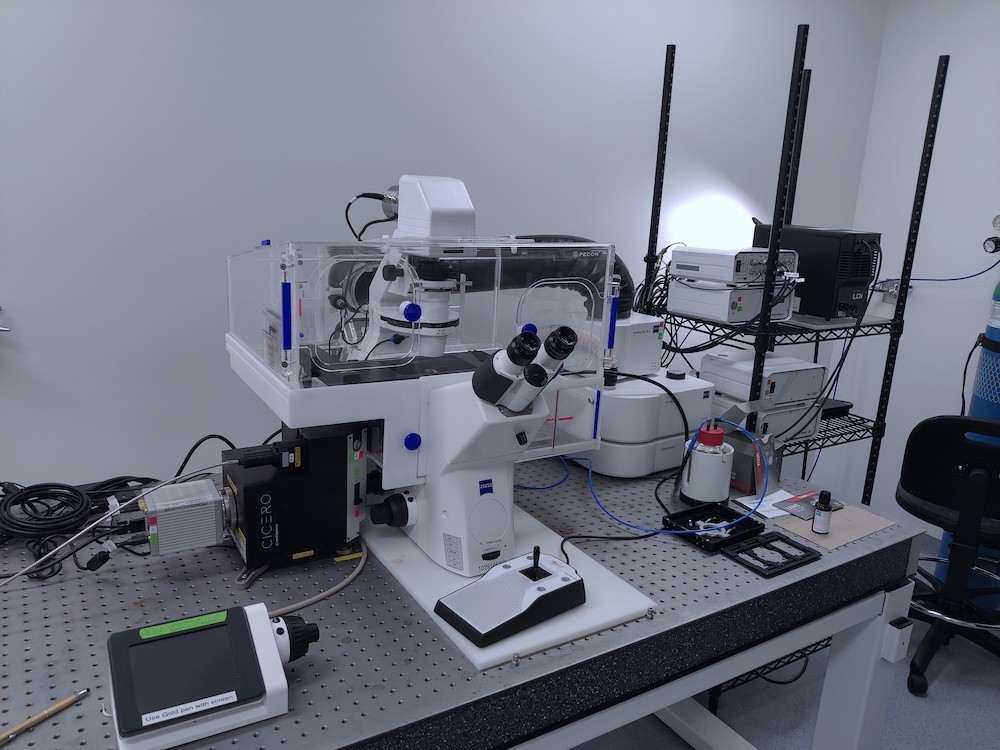

In Electron Back scatter Diffraction, researchers usually use polished sections of material—metal, ceramic, or a geological specimen—to expose a flat surface for analysis. To produce an undistorted diffraction pattern, the sample must be free from contamination, oxidation, and other surface irregularities.

The sample is mounted in a scanning electron microscope (SEM), its surface tilted at a steep angle (usually 70°) to the electron beam. This beam interacts with the sample surface to scatter electrons, form diffraction patterns, and analyze them for the material’s crystal structure, grain orientation, and phase information.

Advantages & Limitations of EBSD (Electron Backscatter Diffraction)

Some of the advantages & limitations of EBSD are tabulated below:

| Advantages | Limitations |

| High-Resolution Crystallographic Information | Surface Sensitivity |

| Phase Identification | Spatial Resolution Limitations |

| Grain Boundary Analysis | Time-Consuming |

| Texture Analysis | Material Limitations |

| In-situ Analysis | Data Interpretation Complexity |

EBSD Test Conclusion

EBSD (Electron Backscatter Diffraction) is a powerful and versatile technique widely used in materials science, geology, and engineering for detailed crystallographic analysis. It provides high-resolution information on grain orientation, phase identification, and microstructural characteristics, making it an indispensable tool for researchers and engineers.

FAQs on Electron Backscatter Diffraction (EBSD)

It is a powerful and versatile analytical technique widely used for detailed crystallographic analysis in materials science, geology, and engineering.

EBSD is primarily used to analyze the crystallographic structure of materials. It helps determine grain orientation, phase identification, texture analysis, and microstructural characterization.

EBSD directs an electron beam onto a tilted, polished sample within a scanning electron microscope (SEM). The electron beam's interaction with the sample surface causes electrons to scatter, forming diffraction patterns. A detector captures and analyzes these patterns to reveal information about the material's crystal structure, grain orientation, and phase.

EBSD is most effective for analyzing crystalline materials, including metals, ceramics, and minerals.

While EBSD is a powerful technique, it has limitations, including surface sensitivity, limited spatial resolution compared to other methods like TEM, and a shallow penetration depth.

3 Easy Steps to Start Testing

Case Studies

In-depth examination of genuine material testing solutions

Dopant and ultra-low concentration elemental analysis using Scanning…

EELS analysis of gate and channel is performed on fin field-effect transistors (finFETs). Scanning transmission electron...

Read Case StudyAnalysis of degradation of PVC pipe using Fourier…

Introduction PVC is the polymer primarily used to make pipes for plumbing, drainage, and electrical conduits....

Read Case StudyNano-scale roughness measurement of Si-wafers by Atomic Force…

Nano-scale surface roughness is a critical parameter in fabricated thin-films that are used in optics, solar...

Read Case StudyTalk to Our Experts Today!

Submit your contact info and we’ll get back to you within 24 hours