Corrosion is commonly understood to mean rusting in common usage. Corrosion, however, encompasses far more than this “simplified” explanation would lead one to believe. Corrosion is the process through which a material deteriorates as a result of a chemical reaction with its surroundings.

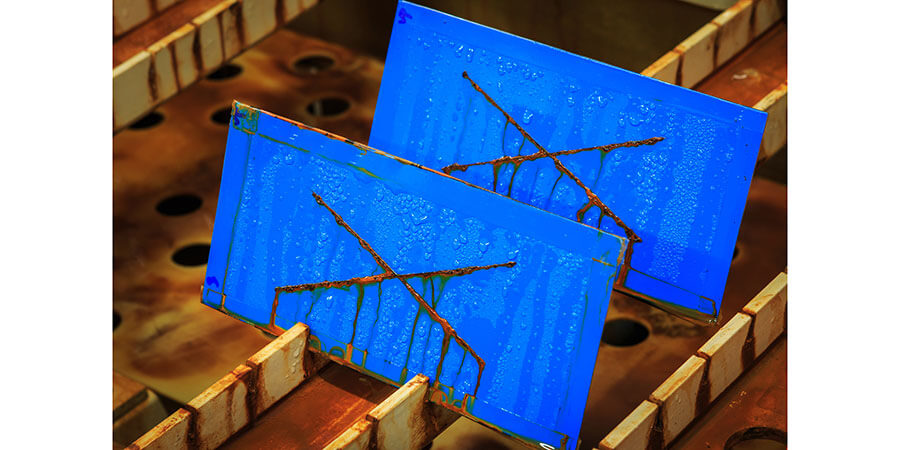

Although corrosion is a common occurrence that is frequently confused with rusting, its reach goes well beyond this oversimplified idea. Materials gradually deteriorate as a result of chemical interactions with their surroundings. Corrosion is a major issue in many different industries since it can lead to functional limitations including tears, fissures, or full wear of components. The comprehensive framework provided by DIN EN ISO 8044 defines and describes words relating to corrosion damage, appearance, and protection, including a variety of corrosion forms.

One instance of corrosion is seen in steels made of chromium, where grain boundaries can show signs of galvanic corrosion, pitting corrosion, and intergranular corrosion. Silver tarnishing, steel embrittlement through exposure to hydrogen, and iron corrosion are typical examples. Infinita Lab provides invaluable materials and knowledge for gaining a greater understanding of the intricacies, causes, and analytical methods of corrosion. Corrosion is a crucial topic of study and research in engineering and materials science because it must be understood and minimized to maintain the integrity and dependability of materials and components in a variety of applications.

There are many different ways that corrosion might start. Surface contamination by electrolytes, which results in the electrochemical oxidation of metals, is one frequent reason. Additionally, mechanical stress can cause corrosion by removing protective layers on the metal’s surface known as passivation. Corrosion is a major concern in many different sectors and applications because these processes can jeopardize the integrity of materials and components. To reduce the negative effects of corrosion and maintain the durability and dependability of structures and equipment, preventive measures and the right material selection are crucial.

In their lab, scientists use a variety of analytical techniques to study corrosion. These techniques offer insightful information on the corrosion process and aid in the selection of preventative measures. Scanning Electron Microscopy (SEM/EDX), which permits precise imaging and elemental analysis, is one of the technologies available. The chemical composition of surfaces is also studied using X-ray Photoelectron Spectroscopy (XPS or ESCA), which provides important information on corrosion mechanisms. Additionally, surface chemistry research and molecular species identification are done using Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS). These cutting-edge analytical methods are essential for comprehending and resolving corrosion-related problems, ensuring the resilience and dependability of materials and structures.

Utilizing cutting-edge analytical techniques, Infinita Lab provides an efficient investigation of corrosion damage and its underlying causes in a variety of components and materials. The lab concentrates on comprehending the damage patterns linked to different types of corrosion and carefully examines the chemical makeup of corrosion deposits and residues. Additionally, the efficacy of existing safety measures, such as present shields, is evaluated. Infinita Lab seeks to offer insightful explanations of what went wrong and offers professional advice on mitigating future occurrences by locating the corrosion’s core causes. To handle corrosion-related problems and guarantee the long-term integrity and dependability of their materials and constructions, clients can get in touch with the lab for assistance.

Video 01: Corrosion Analysis

In-depth examination of genuine material testing solutions

EELS analysis of gate and channel is performed on fin field-effect transistors (finFETs). Scanning transmission electron...

Read Case StudyIntroduction PVC is the polymer primarily used to make pipes for plumbing, drainage, and electrical conduits....

Read Case StudyNano-scale surface roughness is a critical parameter in fabricated thin-films that are used in optics, solar...

Read Case StudySubmit your contact info and we’ll get back to you within 24 hours