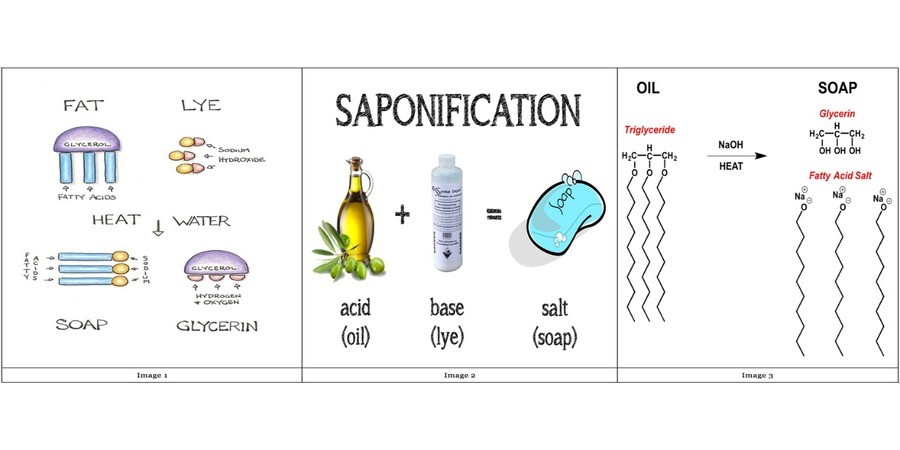

Tests for soap composition take place during the soap formation process, which involves mixing lye and oil—a reaction known as “saponification.” During saponification, lye reacts with the triglycerides in the oil to produce soap and glycerol. This crucial reaction is central to soap processing and significantly impacts the texture and performance of the final product. Laboratory tests are integral in producing high-quality soap, as they assess its composition, purity, and safety. These tests are essential for both small-scale and commercial soap manufacturers. So far, we have answered the question what is saponification? This paper uses some of the principal laboratory tests to examine the chemical composition of soap both during and after saponification.

In this competitive scenario of the soap manufacturing business, the chemical composition of soap bars must be accurate. As a process, soap composition testing applies advanced laboratory techniques to ensure both product resilience and safety. It starts with the precise weight measurements of the ingredients used, such as the oils and alkalis mix, to start saponification. Indeed, it is a necessary chemical process that can only occur with the introduction of lye. In this regard, at an industrial level, a complete understanding of the exact composition of these ingredients becomes imperative in the interest of quality control and meeting safety standards.

One simple test is the saponification value test, which measures the total number of molecular weights related to fatty acids. This test can indicate something about the purity and concentration of fat used. Another crucial test is the pH strip test, which tests for the soap bar’s completeness, thus assuring consumers that the soaps are safe for use.

A determination performed for a prominent soap manufacturer revealed variations in saponification tests of the soap composition process. These variations were corrected by modifying the fat-to-lye ratios. This resulted in a 20% increase in product consistency and lessened production waste.

The Soap testing related methodologies are as follows:

| Methodologies | Description |

| Heavy Metals Analysis: | The test is for hazardous elements to human health, such as mercury, lead, and arsenic. Soaps should not contain certain toxins for safety, which needs to be considered regarding the public interest. |

| TFM Testing: | Determining the water content in soap is very useful since excess water reduces the shelf life of the soap, which is the time it takes to start disintegrating. This analysis will enable the producers to better regulate the quality of the soap, either during manufacturing or during storage. |

| Measurement of Glycerine Content | Glycerin is another valuable coproduct of Tests for Soap Composition or saponification. Adding glycerin can further enhance soap’s moisturizing properties. Checking the glycerine content of soaps ensures the truth behind claims of moisturizing properties. |

| Moisture Content Analysis | This test determines the number of insoluble particles in the soap. An abundance of such dirt could make the soap cloudy and clog the drain pipes. A low limit of insoluble matter helps ensure the aesthetic quality of soap bars. The above-described additional testing procedures satisfy customers’ and local industry requirements and demand by providing more in-depth product safety and quality information. |

| Performance testing | The product is tested for lather ability, instability, skin irritation potential, and water quality. These tests help formulate soaps that meet consumer expectations and function efficiently over various usage scenarios. |

| Test for Insoluble Matter | This test determines the number of insoluble particles in the soap. An abundance of such dirt could make the soap cloudy and clog the drain pipes. A low limit of insoluble matter helps ensure the aesthetic quality of soap bars.The above-described additional testing procedures satisfy customers’ and local industry requirements and demand by providing more in-depth product safety and quality information. |

Extensive testing of soap enhances customer satisfaction and trust, ensuring the safety and quality of the final product. Manufacturers comment on their strict control of product parameters by measuring moisture content, total fatty matter testing, and insoluble matter testing to ensure they meet consumer requirements and the legal standards of most countries. The content measurement for glycerine and heavy metal analyses is done to ensure safe soap production for its users. Lastly, the performance test is also done, such as latherability and rinsability, to ensure it works appropriately under any condition occurring in real life, therefore living up to its international brand commitment to the customers. These, hence, are necessitated in the continuous chase to offer better and safer soap products on the market.

Soap formation takes place by mixing lye and oil. This process is known as "saponification."

The key tests performed during the saponification process are: PH testing, Titration. Free fatty acid test, Moisture content analysis test.

Saponification occurs between 60 to 80 degrees of temperature for 15-60 minutes.

Saponification is an exothermic process.

In-depth examination of genuine material testing solutions

EELS analysis of gate and channel is performed on fin field-effect transistors (finFETs). Scanning transmission electron...

Read Case StudyIntroduction PVC is the polymer primarily used to make pipes for plumbing, drainage, and electrical conduits....

Read Case StudyNano-scale surface roughness is a critical parameter in fabricated thin-films that are used in optics, solar...

Read Case StudySubmit your contact info and we’ll get back to you within 24 hours