Guide to Scanning Electron Microscopy (SEM): Principles, Applications & Testing Solutions

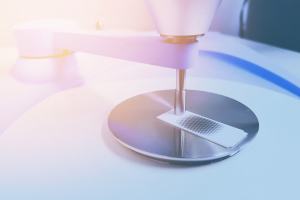

Scanning electron microscopy (SEM) is a surface analysis method that is widely used to determine the surface characteristics of sub-micron sized particles. With the diminishing working scales of materials used in various industries like microelectronics, SEM has far-reaching applications like semiconductor inspections, microchip assembly, failure analysis, and quality control. Laboratory professionals at Infinita Lab guarantee the optimum application of the SEM technology for general and targeted testing of your products, providing the best performance, lower warranty costs, and high levels of customer satisfaction.

TRUSTED BY

Precision-driven testing for dimensional accuracy and compliance

- Overview

- Scope, Applications, and Benefits

- Test Process

- Specifications

- Instrumentation

- Results and Deliverables

Overview

Scanning Electron Microscopy (SEM) is an advanced analytical surface technique used to study morphology, microstructure, and composition in materials at submicron to nanometer scales. SEM focuses electrons as a beam to produce high-resolution images and analytical data. It is becoming an indispensable technique for industries with decreasing material dimensions and tolerances, such as microelectronics, semiconductors, aerospace, and biomedical devices.

It provides detailed information on surface topography, material defects, and elemental composition, thereby supporting quality control, failure analysis, and product optimization.

Scope, Applications, and Benefits

Scope

SEM enables detailed characterization of solid materials by analyzing:

- Surface morphology and topography (3D-like imaging)

- Material contrast based on atomic number

- Elemental composition through Energy-Dispersive X-ray Spectroscopy (EDS)

It is suitable for conductive and non-conductive materials (with appropriate sample preparation) across a wide range of industrial and research applications.

Applications

- Semiconductor inspection and microchip assembly analysis

- Failure analysis of electronic components and coatings

- Evaluation of thin films and surface coatings

- Identification of microstructures, inclusions, and contaminants

- Corrosion and fracture analysis of metals and alloys

- Polymer degradation and filler dispersion analysis

- Mineral identification and ore quality assessment

Benefits

- Delivers ultra-high-resolution imaging beyond optical microscopy

- Combines imaging with elemental and compositional analysis

- Detects early-stage defects, reducing product failure and warranty costs

- Supports product development, quality assurance, and root-cause analysis

- Applicable across diverse industries from aerospace to biomedicine

Test Process

Specimen Preparation

Solid samples are cleaned and, if non-conductive, coated with gold or carbon to prevent charging.

1Electron Beam Scanning

A focused electron beam scans the sample surface at controlled accelerating voltages (typically 0.1–30 kV).

2Signal Detection

Secondary electrons, backscattered electrons, and X-rays are detected using dedicated detectors.

3Data Collection & Imaging

Signals are processed to generate high-resolution images and elemental maps (EDS).

4Technical Specifications

| Parameter | Details |

|---|---|

| Imaging Resolution | Down to the nanometer scale |

| Signal Types | Secondary electrons (SE), Backscattered electrons (BSE), X-rays (EDS) |

| Sample State | Solid materials |

| Accelerating Voltage | Typically 0.1–30 kV |

Instrumentation Used for Testing

- Scanning Electron Microscope with electromagnetic lenses

- Secondary Electron (SE) detectors

- Backscattered Electron (BSE) detectors

- Energy-Dispersive X-ray Spectroscopy (EDS) system

- Vacuum chamber and electron gun

- Image acquisition and analytical software

Results and Deliverables

- High-resolution SEM images of surface morphology

- Identification of cracks, pores, inclusions, and defects

- Elemental composition and distribution maps (EDS)

- Comparative analysis of material phases and contaminants

- Failure analysis insights and quality assessment reports

Case Studies

In-depth examination of genuine material testing solutions

Dopant and ultra-low concentration elemental analysis using Scanning…

EELS analysis of gate and channel is performed on fin field-effect transistors (finFETs). Scanning transmission electron...

Read Case StudyAnalysis of degradation of PVC pipe using Fourier…

Introduction PVC is the polymer primarily used to make pipes for plumbing, drainage, and electrical conduits....

Read Case StudyNano-scale roughness measurement of Si-wafers by Atomic Force…

Nano-scale surface roughness is a critical parameter in fabricated thin-films that are used in optics, solar...

Read Case StudyFrequently Asked Questions

It is a high-resolution surface imaging technique that provides a magnified image of the sample scanned using electron beams.

SEM is widely used in various fields including: Material Science, Biology, Electronics, Forensics, etc.

SEM provides several advantages: High Resolution, Field Depth, Versatility.

Request a Quote

Submit your material details and receive testing procedures, pricing, and turnaround time within 24 hours.

Quick Turnaround and Hasslefree process

Quick Turnaround and Hasslefree process

Confidentiality Guarantee

Confidentiality Guarantee

Free, No-obligation Consultation

Free, No-obligation Consultation

100% Customer Satisfaction

100% Customer Satisfaction