Powder X-ray diffraction (PXRD) is one of the standard methods for characterizing nanoscale materials. A practical, non-destructive analytical method for examining the phase composition, crystal structure, and orientation of powder, liquid, and solid samples is X-ray diffraction (XRD). This Non-Destructive method is primarily used for phase identification of a crystalline material and delivers information on unit cell dimension. The original material is finely ground and homogenized, and the average bulk composition is determined. Powder XRD analysis of a sample provides several pieces of information necessary, complementary to various microscopic and spectroscopic methods, including phase identification, sample purity, crystallite structure size, and, in many instances, morphology. Although widely available and necessary, researchers only sometimes exploit this information in nanoscale materials data and sometimes misinterpret it.

Powder X-ray diffraction can usefully determine the structure, phase, content, size, shape, crystallinity, and other significant characteristics of nanoscale materials; however, unambiguous sample characterization nearly always necessitates complementing experimental and computational techniques. Since it’s a bulk method, the data it yields can be compared to data from microscopy to see if microscopic observations on a tiny sample of particles accurately reflect the majority of the sample. Powder XRD data for nanoscale materials can often be straightforward to analyze for the vital information needed, but at other times, it can be pretty complex.

PXRD has a broad scope, encompassing various fields such as

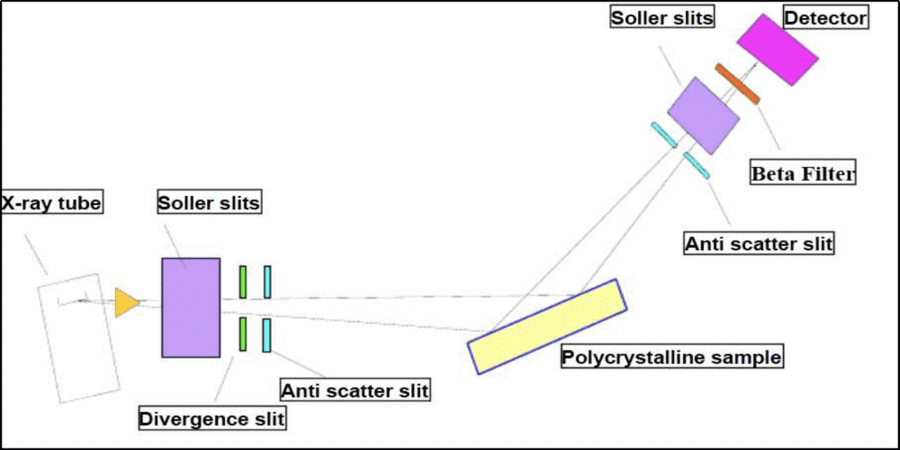

How does powder X-ray diffraction work?

Crystal structure determines the pattern in which diffraction of X-rays occurs. Instead of obtaining the diffraction pattern from a single crystal structure, the X-ray powder diffraction method uses a powdered version of the material. This is often much easier and more convenient than single-crystal diffraction because growing single crystals is not required. XRD on powder also provides a diffraction pattern for the bulk material of a crystalline structure solid and not for just a single crystal, which may or may not be representative of the whole material.

Read more: X-ray Powder Diffraction (XRD)

The general procedure for PXRD involves the following steps:

The powdered sample is loaded onto a sample holder, usually made of non-crystalline material, to avoid background noise.

This improves spatial resolution by concentrating high- and low-energy electrons at a low electrical potential (about 0.02 to 5 kV).

The sample is placed in the X-ray diffractometer and exposed to X-rays, which are then detected at different angles by the diffracted rays.

A diffraction pattern is created by measuring the intensity of the diffracted X-rays as a function of the angle. The last stage is the sample and data analysis stage.

The following are the sample size and data Interpretation of Powder X-ray diffraction:

| Sample Size | Result |

A few milligrams to a few grams are needed for P-XRD analysis (10 to 50 mg ) | PXRD results involve interpreting the diffraction patterns to derive structural information such as Peak Identification, Phase Identification, Quantitative Analysis, and Crystallographic Information. |

The following are the limitations and strengths of Powder X-ray diffraction:

| Limitations | Strengths |

| Overlay of peaks may occur, which can worsen reflections. | This powerful and rapid technique takes less than 20 minutes to identify an unknown mineral. |

| Indexing patterns for non-isometric crystal systems are complicated for unit cell determinations. | Data interpretation is relatively straightforward. |

| The sample must be ground to powder to the tenth of a gram. | Minimal sample preparation is required. |

| The detection limit of mixed materials is usually ~ 2% of the sample. | Data interpretation is relatively straightforward. |

PXRD has numerous applications across different fields, such as Material Characterization, which involves Determining phase purity, identifying unknown phases, and studying phase transitions in various materials.

X-ray powder diffraction is a multi-capable and powerful analytical technique for characterizing crystalline materials. Due to its excellent information on material structure, composition, and properties, this technique has become indispensable in many scientific and industrial areas. As technology advances, PXRD continues to evolve, offering even greater precision in the complex world of crystalline materials.

X-ray powder diffraction is the most used method for assessing the initial solid state of dry powders and the change in the solid state following exposure to humidity and/or higher temperature.

Powder X-ray diffraction determines the phases and purity of a crystalline species. Single X-ray diffraction identifies the atoms in a crystal and their locations, electron densities, bond lengths, and angles.

A sample can include 2 to 5 grams of powder to provide an exact amount for XRD analysis. 0.7 grams of powder is enough to take XRD samples. In some cases, the powder is spilled out during filling. In such cases, 1.5 grams may be needed.

The size of the crystal is inversely related to the peak width. A thinner peak represents a giant crystal. A broader peak indicates that the sample may be amorphous or a solid with imperfect crystallinity, or it may indicate a minor crystal defect in the crystalline structure.

In-depth examination of genuine material testing solutions

EELS analysis of gate and channel is performed on fin field-effect transistors (finFETs). Scanning transmission electron...

Read Case StudyIntroduction PVC is the polymer primarily used to make pipes for plumbing, drainage, and electrical conduits....

Read Case StudyNano-scale surface roughness is a critical parameter in fabricated thin-films that are used in optics, solar...

Read Case StudySubmit your contact info and we’ll get back to you within 24 hours