The medical device has witnessed massive growth in the past few decades, and medical device testing has become very crucial. This industry, like many others, is constantly evolving, offering advanced medical instruments and technologies that are transformative in function. For instance, there are pacemakers and insulin pumps. These apparatus are central in diagnosing, treating, and managing a wide range of medical conditions.

As applied science advances, the sector continues to expand, pushing the boundaries of healing art and innovation. However, with it comes the responsibility of ensuring that all medical devices are both safe and effective. This is where medical device testing becomes crucial.

Testing validates the quality and reliability of medical devices. It ensures that they meet established standards and perform consistently across different environments. High-quality devices contribute to better patient outcomes.

Medical device testing is not just a regulatory requirement but a fundamental aspect of product development that guarantees devices operate within the predefined scope given a variety of conditions and interactions. It covers a wide array of inspections designed to cross-check everything from biological compatibility and sterility to functionality and user interface. The outcome of these substantiations determines whether a medical device is ready for public use or not.

Additionally, as the regulatory landscape continues to tighten, the importance of robust medical device examination cannot be overstated. This is because patients’ safety is at stake; hence, manufacturers must navigate the bureaucratic requirements needed to ensure their devices can withstand rigorous examination protocols.

The regulatory landscape of medical device testing is structured and enforced by authoritative bodies to ensure that all medical devices released into the market are safe and effective. In the United States of America, the Food and Drug Administration institution is the primary regulatory authority that sets standards and issues approvals for medical devices. The FDA classifies devices into three based on the risk they pose to patients.

These categorizations are Class I (considered low), Class II (regarded as moderate), and Class III (appraised as high). Each class requires a different level of regulatory control, with Class III devices undergoing the most stringent premarket approval process.

Understanding the specific classification and corresponding requirements is crucial for manufacturers to navigate the approval process efficiently. The stratification influences the extent of testing needed, including aspects like biological compatibility, sterility, and performance.

Class I instruments like bandages and hand-held surgical apparatus generally require less comprehensive testing when compared to Class III, which include heart valves and implantable pacemakers among others. These are subjected to rigorous assessments and regulatory review.

Furthermore, compliance with global standards such as those from the International Organization for Standardization (ISO) is often essential for worldwide market access. This means that manufacturers must stay informed on these standards as well as changes as they unfold. It is also notable to state that there may be variations to these laws across different regions and countries, which affects how devices are tested and approved all over the world. This is why the regulatory landscape is an important component that shapes the entire process of medical device testing while ensuring that only safe and effective equipment reaches the patients who need them.

The industry demands rigorous evaluation to ensure that products are safe, effective, and meet regulatory standards. The following explores the top five methods relevant to the whole point, with each essential for verifying various aspects of a device’s functionality and safety before it floods the market.

Biological compatibility is a key component of this evaluation, especially for apparatus that are implantable or come into contact with bodily fluids. It ensures that the materials used for the product are well suited to human tissues and fluids, thereby minimizing the risk of rejection, inflammation, or adverse reactions when put to use.

This is a mainspring of medical device validation that ensures devices function as intended under various conditions. It is a rigorous phase that confirms the effectiveness and reliability of medical devices, safeguarding user safety and the device’s efficacy.

Performance testing, on the other hand, plays a pivotal role in validating devices’ safe and effective performances within their intended operational parameters. This is accomplished by thoroughly assessing a device’s functionality scientifically, which helps manufacturers ascertain the reliability of their products, while building trust among healthcare providers and patients.

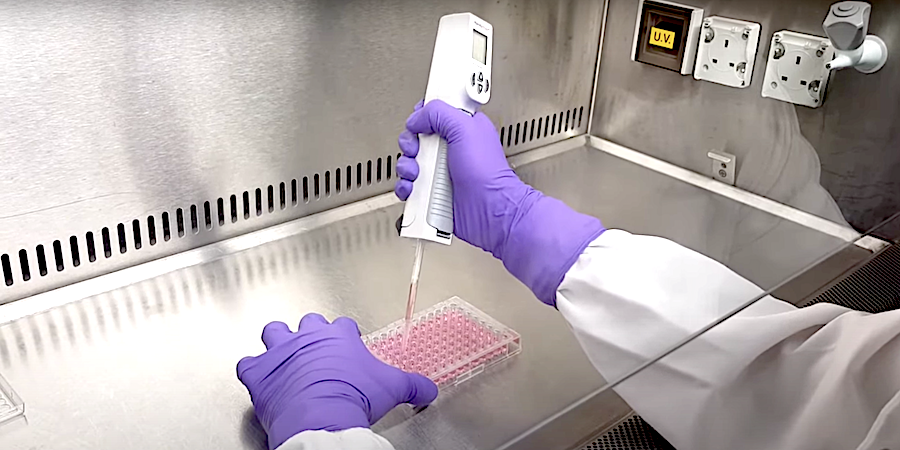

This is employed to ascertain that tools used in surgeries or for other invasive procedures are free from harmful microorganisms. It is vital because any contamination on these devices could lead to infections in patients, complicating their recovery and potentially leading to serious health issues.

Sterility testing is essential for protecting patients from infections and ensuring that medical apparatus are safe and effective when they are used for treatments. Meticulous testing and continuous monitoring help manufacturers to maintain high standards of cleanliness and safety.

This is a method that focuses on the functionality of health gadgets in terms of ease of use as well as safety for associated professionals and patients alike. A user-friendly product is likely to have successful implementations as opposed to the opposite. Such a product will reduce the risk of errors, enhance patient care, and increase the satisfaction of healthcare providers.

Usability examination ensures that medical equipment are not just technically competent but also meet certain needs like end-users’, safety, effectiveness, and user-friendliness. The evaluation is essential for developing products that healthcare professionals can rely on anytime and anywhere.

These are approaches that contribute also to ensuring the overall excellence and reliability of medical devices.

These tests guarantee that medical devices will perform as expected in various environments and throughout their intended lifespan, maintaining high standards of safety and effectiveness.

Material testing is a fundamental aspect of medical device testing that significantly influences the performance, safety, and biocompatibility of these crucial health tools. Comprehending and selecting the properties of materials used in health apparatus are key to ensuring that they function as intended as well as being safe for patients’ use.

Comprehensive medical device testing is central to ensuring the following: patients’ safety, achieving regulatory compliance, and securing marketplace success. This evaluation includes biocompatibility, performance, sterility, and usability testings, which are essential to ascertaining that health apparatus function effectively and safely in the real-world.

At Infinita Lab, we specialize in comprehensive material testing for health tools. Our services encompass:

Our expertise in material testing helps manufacturers or medical equipment navigate the complex landscape of product development, ensuring their devices are safe, effective, and ready for public use. Visit our website to learn more about specialized testing services and get assistance with your medical device development needs.

For expert advice and specialized solutions in medical device testing, we invite you to contact Infinita Lab. Our team is equipped to guide you through every step of the process while ensuring your medical devices meet all necessary standards and regulations. Reach out today, and ensure your products are ready and reliable for public use.

Other Useful Resources

Semi conductor laboratory

Application of uv spectroscopy

Scanning electron microscope testing

Differential scanning calorimetry testing

High performance liquid chromatography testing

In-depth examination of genuine material testing solutions

EELS analysis of gate and channel is performed on fin field-effect transistors (finFETs). Scanning transmission electron...

Read Case StudyIntroduction PVC is the polymer primarily used to make pipes for plumbing, drainage, and electrical conduits....

Read Case StudyNano-scale surface roughness is a critical parameter in fabricated thin-films that are used in optics, solar...

Read Case StudySubmit your contact info and we’ll get back to you within 24 hours