Material selection plays a pivotal role in the volatile world of contemporary engineering. Understanding a material’s properties and ensuring product quality is of supreme importance. A material’s functional integrity and strength can only be determined through material testing. The Leeb Hardness Test emerges as a valuable tool for engineers in this field. For engineers seeking to assess the hardness of metallic materials, this test emerges to be the most versatile, rapid, and portable option.

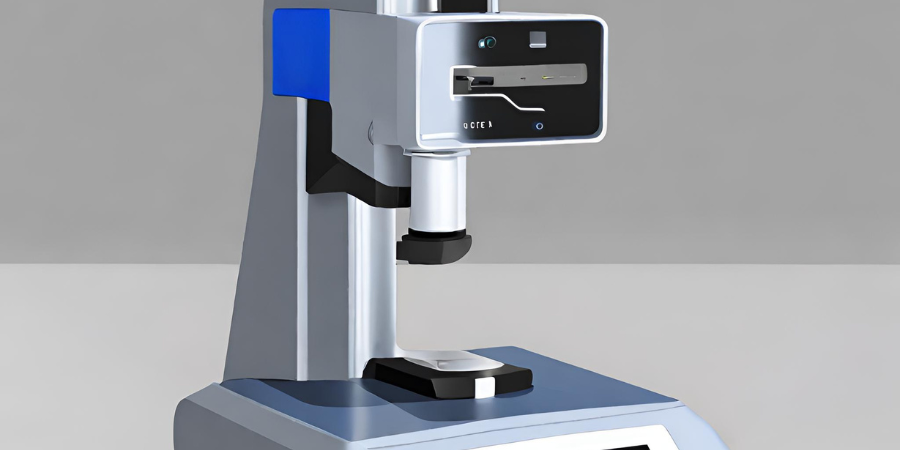

Among numerous traditional methods like Rockwell, Brinell, and Vickers the Leeb Hardness Test offers a distinct advantage over others. Unlike these techniques which are stationary and immobile, the Leeb method leverages a portable testing instrument, facilitating on-site assessments at a significantly lower cost. This translates to greater accessibility and flexibility for engineers, enabling them to conduct hardness evaluations directly within production environments.

The core principle of the Leeb method revolves around measuring energy loss. During the test, an impact body strikes the metallic surface. The resulting loss of energy due to material deformation is meticulously measured, expressed as the Leeb quotient. This quotient directly correlates with the material’s hardness – a higher Leeb hardness (HL) value signifies greater resistance to deformation, as evidenced by the faster rebound of the impact body.

Leeb hardness testers offer significant advantages beyond portability and cost-effectiveness:

While the core advantages of the Leeb Hardness Test have been explored, several noteworthy aspects deserve further attention:

Infinita Lab (https://infinitalab.com/) is a forerunner in the field of material science testing. We have built our reputation on a foundation of trust and reliability by offering an exhaustive array of over 2,000 tests catering to diverse industries. Engineers from many Fortune 500 companies choose us for our commitment to delivering timely, accurate, and dependable testing services. We have expertise that extend to the Leeb Hardness Test and beyond. Our commitment to client success is reflected in the services we offer:

The Leeb Hardness Test has emerged as a powerful and versatile tool within the domain of material science testing. For those engineers seeking a cost-effective and efficient approach to evaluate the hardness and damage resistance of metallic materials, the Leeb Hardness Test presents a compelling solution. It offers numerous advantages like portability, minimal surface preparation, and quick testing capabilities over traditional methods of testing. The ability to assess a larger surface area and, in some cases, curved surfaces, further expands its applicability across diverse applications. The Leeb Hardness Test signifies a significant advancement in material science testing. Its efficiency and flexibility make it an invaluable asset for engineers seeking to optimize material performance. You gain invaluable insights into the hardness and resistance of your materials by including this test in your evaluation process. Ultimately leading to a product with better design and optimal performance.

Engineers can gain invaluable insights that lead to the development of stronger, dependable, and higher-performing products by incorporating this test into their evaluation and selection processes. As technology continues to evolve the Leeb Hardness Test is set to remain a valuable asset for engineers pushing the boundaries of innovation in material science.

Video 01: Mad Metrology Minute – Leeb style hardness tester

Other Useful Resources

Application of uv spectroscopy

Differential scanning calorimetry testing

High performance liquid chromatography testing

In-depth examination of genuine material testing solutions

EELS analysis of gate and channel is performed on fin field-effect transistors (finFETs). Scanning transmission electron...

Read Case StudyIntroduction PVC is the polymer primarily used to make pipes for plumbing, drainage, and electrical conduits....

Read Case StudyNano-scale surface roughness is a critical parameter in fabricated thin-films that are used in optics, solar...

Read Case StudySubmit your contact info and we’ll get back to you within 24 hours