Metallurgical Testing - Enhancing Durability and Reliability

Introduction to Metallurgical Testing Services

Metallurgical testing plays an important part in the strength, reliability, as well as the safety of the metal as well as alloys used in industry applications for aerospace, automobile, building construction, as well as energy. Infinita Lab also offers full metallurgical testing services, which may provide precise material characteristics as well as performance. It enables our manufacturers to design product life for optimum performance, as well as deliver consistent performance high-grade materials for critical applications.

Importance of Metallurgical Testing

Metallurgical testing provides essential information on a material’s microstructure, mechanical properties, and environmental resistance. These insights help manufacturers:

- Understand material behavior under stress and environmental conditions

- Discover weaknesses or defects before the occurrence of failures

- Maximise strength as well as production processes and product design for safety purposes

Precise metallurgical analysis provides less risk, increased product reliability, and flexibility for development of the emerging industry.

Metallurgical Testing Services Offered

Infinita Lab conducts complete-spectrum metallurgical test services employing the best analytical techniques as well as the finest equipment available for the purpose of examining the alloys’ as well as metals’ mechanical, chemical, as well as structural properties. Their test services help manufacturers, researchers, as well as engineers, authenticate the quality, performance, as well as reliability of their materials for their most crucial applications in aerospace, auto, building constructions, energy projects, as well as others.

Microstructure Examination

Microstructure characterization discloses the internal features of the metal’s architecture, grain constitution, phase constitution, inclusions, and defects. Examination on these characteristics significantly contributes to the behavior of the materials at working stress, at heat cycles, or at exposures. It contributes toward the identification of the potential weaknesses at an early development stage, aids the quality control check, and ensures the materials for their performance criteria for severe applications.

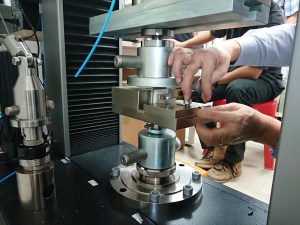

Mechanical Testing

- These also check the metal’s strength, elasticity, toughness, as well as resistance to deformation or breaking.

- In the test for varying temperatures, loadings, and also for stresses, the materials need to meet not only design requirements but application requirements.

- These tests provide valuable data for the selection of the right materials for high performance applications, such as construction components, engine parts, and aircraft alloys.

Failure Analysis

Failure analysis explores the underlying causes of component or material failure, whether it resulted from mechanical overload, corrosion, fatigue, or defects during manufacturing. Knowing the root causes, Infinita Lab offers practical recommendations for designs for improvement, future prevention of failures, and increasing the overall reliability and durability of metal parts.

Corrosion Testing

Corrosion testing ascertains resistance of the material toward oxidation, moisture, chemicals, as well as environmental degradation. It’s particularly relevant for metals used in harsh or distinct environments such as marine use, oil/gas lines, chemical process equipment. Knowing the corrosion behavior allows the manufacturer to use the appropriate surface treatment, coating, or methods of material choice for enhancing the service life as well as maintaining the safety requirements.

Infinita Lab: Your Material Testing Partner

Contact Infinita lab for Metallurgical testing by major benefits like:

- End-to-end testing management, faster turnaround, reduced administrative burden.

- Confidence in accurate results and reduced stress in vendor coordination.

- Enhanced reputation for product reliability and innovation.

- Engineers and R&D managers focus on core work rather than testing logistics.

Looking for a trusted partner to achieve your research goals? Schedule a meeting with us, send us a request, or call us at (888) 878-3090 to learn more about our services and how we can support you. Request a Quote

Essential FAQs on Metallurgy Materials Testing Services

Metallurgical testing should ideally be conducted at various stages throughout the product lifecycle to ensure quality and performance. Initially, it’s crucial during the design and prototyping phase to select suitable materials and manufacturing processes. During production, regular testing ensures consistency and detects any deviations or defects early on. Post-production, testing verifies the integrity and durability of the final product, guaranteeing it meets performance standards and customer expectations. Additionally, periodic testing during service life helps monitor degradation, assess wear, and inform maintenance or product improvement decisions. Overall, integrating metallurgical testing throughout the lifecycle ensures product reliability and longevity.

Infinita Lab guarantees the precision and dependability of its metallurgical testing services through a rigorous quality assurance framework, employing highly qualified metallurgists and utilizing state-of-the-art analytical equipment. Our labs adhere to strict international standards and protocols, ensuring each test is conducted with meticulous attention to detail. Regular calibration of our instruments, coupled with continuous staff training, maintains our high standards of accuracy and reliability. By integrating advanced technology and expert analysis, Infinita Lab delivers consistent, accurate results, providing our clients with a foundation of trust and confidence in their material selection and product development processes.

Initiating metallurgical testing services with Infinita Lab is a streamlined and customer-focused process. It begins with a consultation where you reach out to our team with your specific testing requirements. Our experts engage with you to understand your needs in depth, advising on the most appropriate tests to meet your objectives. Following this, we provide a detailed quote and timeline for the testing services. Once agreed upon, we coordinate the logistics of sample collection and testing through our network of specialized labs across the U.S. Throughout the process, we ensure transparent communication, keeping you informed and involved at every step, from initial inquiry to the delivery of final results.

What distinguishes Infinita Lab’s metallurgical testing services is our unparalleled commitment to quality, efficiency, and customer collaboration. Unlike competitors, Infinita Lab leverages a vast network of specialized labs across the U.S., enabling access to over 2000 tests and ensuring comprehensive coverage for any metallurgical analysis need. Our unique approach prioritizes a seamless client experience, from initial consultation to final reporting, tailored specifically to each project’s requirements. Coupled with our team of expert metallurgists and state-of-the-art equipment, Infinita Lab delivers insightful, actionable results with speed and precision that set us apart, making us a trusted partner in advancing our clients’ projects and innovations.

Infinita Lab has an extensive network of material testing facilities throughout the United States, employing cutting-edge technology and methodologies to deliver the utmost precision in calibration and testing services. We offer doorstep sample-pick service across the U.S. Furthermore, we have 16 physical locations across the United States, ensuring a wide-reaching presence to serve clients efficiently. Our offices are strategically situated in Phoenix and Chandler, AZ; Costa Mesa, Irvine, Newark, Pleasanton, San Diego, San Jose, and San Mateo, CA; Chicago, IL; Boston, MA; Durham, NC; New York, NY; Columbus, OH; Portland, OR; and Houston, TX.

3 Easy Steps to Start Testing

Read Our Blogs and Research Papers

ASTM D7264 – Specimen Size

ASTM D7264 – Specimen Size

ASTM D7264 - Specimen Size The ASTM D7264 standard describes two test procedures to determine the flexural properties of composites:...

Read ArticleTypes of Mechanical Testing

Types of Mechanical Testing

TYPES OF MECHANICAL TESTING The broadly used 5 types of mechanical testing are as mentioned below: 1. Mechanical properties: To...

Read ArticleTypes of Vibration Testing

Types of Vibration Testing

TYPES OF VIBRATION TESTING Vibration testing services assess an item's susceptibility to vibration. This testing is carried out to make...

Read ArticleMeet our Team

Best Industry Experts to Help You

Pradyumna Gupta PhD, MBA

Vinay Vidyarthi PhD

Dhairya Srivastava MBA

Rana Pratap PhD

Gautam Kumar PhD

Keisha Antoine PhD

Animangsu Ghatak PhD

Sabyasachi Roy

Srinivas Mettu PhD

Shantanu Behera PhD

Talk to Our Experts Today!

Submit your contact info and we’ll get back to you within 24 hours