Introduction

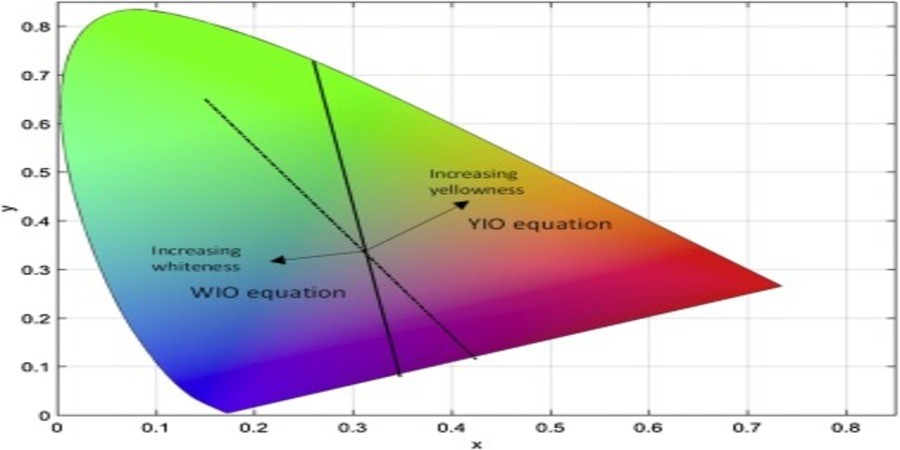

Yellowness Index YI ASTM E313 refers to the degree of yellowness in white or whitish materials. This test is valuable in evaluating color changes brought about by aging or chemical damage. It describes the quality and stability of a product, which leads manufacturing companies through a series of quality control measures. This standard is utilized by the plastics and paper industries in the processing of materials to attain consistency in their products and to please their consumers. Therefore, it ensures that the correct color assessment meets strict industry standards.

Scope

The ASTM E313 test provides the yellowness index of plastics, textiles, and other materials. YI is a significant parameter for evaluating materials’ color quality and stability when exposed to sunlight and other environmental factors. It helps the manufacturers achieve the color of their products per the general specifications of any particular industry while retaining their color appearance over a considerable period.

Test Procedure

The test method calls for the use of a spectrophotometer. The instrument measures the reflectance and transmittance at specific wavelengths. The instrument captures the color data of the specimen for computation of the yellowness index using the same data. The steps in doing so are as follows:

Preparation: Clean the test sample from dirt and contaminants, which will affect the results.

Measurement: Put the sample in the spectrophotometer. The device will measure the reflectance or transmittance at pre-set wavelengths.

Calculation: After obtaining the data, calculate the Yellowness Index using the ASTM E313 formula.

This procedure supports accuracy and ease of repetition in processes to maintain quality throughout production. Therefore,

Data

The information yielded from this test includes the yellowness index value, which quantifies the amount of yellowness in the sample. This value is the first colorimetric data that describes how yellow the material appears under standardized lighting conditions. The lower the YI, the less yellow the material is. These data are essential for comparing materials or tracking changes in the same material over time.

Specimen Size

ASTM E313 dictates the size of the specimen required for testing. It depends on the material to be tested and the type of spectrophotometer. Generally, the sample for most applications should be large enough to cover the measurement port. This provides for full view or the proper field of view by the instrument and yields an accurate measurement. The specimen sizes will vary in dimension and form but mostly range from a square of a few centimeters in the case of a textile material to a sheet face in the case of plastic materials.

Further Analysis:

Beyond simple yellowness index testing, extended testing could involve comparing YI values under different conditions, such as before and after UV exposure or chemical treatments. Such tests help determine the material’s color stability and resistance to environmental factors. Complementary related tests could include tensile strength testing according to ASTM D638 and chemical weathering/UV resistance, which may give further contextualization to the YI analysis regarding the material’s performance.

Tests Involved in Yellowness Index Procedure

Several tests, along with ASTM E313, are involved to offer a comprehensive understanding of the material properties. Some of these are:

| Tests | Description |

| Spectrophotometry Testing | Measurement of the color data needed to calculate the YI is essential. Optical Gloss Testing evaluates the surface gloss of materials, which can influence perceived color. |

| Visual Refractive Index Evaluation | Assesses how light bends through a material, affecting the appearance of its color. |

| Weathering/UV Resistance Testing | This examines how the material’s hue changes when exposed to UV light and weathering conditions. |

| Compatibility Inspection | Investigates how chemical exposure impacts the material’s color stability. |

These tests allow manufacturers to ensure that their products meet all performance requirements for quality and durability.

Result:

The Yellowness Index measures are precise to minimize color inconsistency and discrepancy using the respective materials in the prescribed industries.

Conclusion:

ASTM E 313 allows us to estimate the yellowness index of materials with color standards. This will help manufacturers maintain high-quality products with standard color performance through outlined procedures that include related tests.

FAQs

ASTM E313 Yellowness Index refers to the degree of yellowness in white or whitish materials. This test is valuable in evaluating color changes brought about by aging or chemical damage.

YI is a significant parameter for evaluating materials' color quality and stability when exposed to sunlight and other environmental factors. It helps the manufacturers achieve the color of their products per the general specifications of any particular industry while retaining their color appearance over a considerable period.

The Yellowness Index is measured using a spectrophotometer or colorimeter, which analyzes a material sample's reflected or transmitted light. The instrument calculates the YI value based on the material's spectral data, comparing it to the standard reference value.

YI testing is usually used to control the quality of plastic packaging, paper, textiles, paints, and coatings since it enables monitoring of yellowing upon aging.

Talk to Our Experts Today!

Submit your contact info and we’ll get back to you within 24 hours

Full Spectrum of ASTM Material Testing — Backed by 2,000+ Trusted Lab Partners

ASTM standards for chemical composition, physical properties, failure analysis, and other routine and non-routine testing for polymers and plastics

ASTM standards for determination of mechanical, physical, and thermal properties, and performance of monolithic and composite ceramics

ASTM standards guiding various destructive, non-destructive and analytical tests for quality control of different metals and alloys

ASTM standards for chemical analysis of solid, liquid and gaseous materials for specification compliance and quality control

ASTM standards for various chemical, physical, stability and exposure analysis of paints and coatings

Our Services

Metrology

A variety of microscopy and spectroscopy tools available for precise measurements from the nano to the meter scale.

Learn More

Materials Testing

ASTM and ISO standard and custom chemical, mechanical, thermal, corrosion tests, etc. for all materials metals, ceramic or polymers.

Learn More

Product Testing

Thousands of tests for product quality and reliability under heat, humidity, temperature shock, vibration, drop, electrostatic discharge.

Learn More