Introduction

The ASTM D4541 test measures a coating system’s adherence to metal substrates, commonly known as the pull-off strength Test. This test is helpful when analyzing air barrier installations. Identifying minimum requirements for field installations and product performance in practical settings can be beneficial. The ASTM D4541 test gauges how much strain an adhesive can withstand before a portion of the tested surface disappears. The testing procedure reveals whether the glue withstands a specific level of force. Typically, this testing is graded on a pass/fail basis. The material passes if it holds together when subjected to the required force. A material that gives way under force fails.

Scope

ASTM D4541 is an industry-standard test procedure for determining an air barrier membrane’s pull-off strength. This test is helpful when used to assess air barrier installations and establish minimal requirements to confirm product performance and field installations in actual settings. This test procedure was created to determine metal substrates. It significantly enhances tensile strength and could not produce outcomes equivalent to shear stress tests using various techniques, such as knife adhesion or scratch.

ASTM D4541 Test Procedure

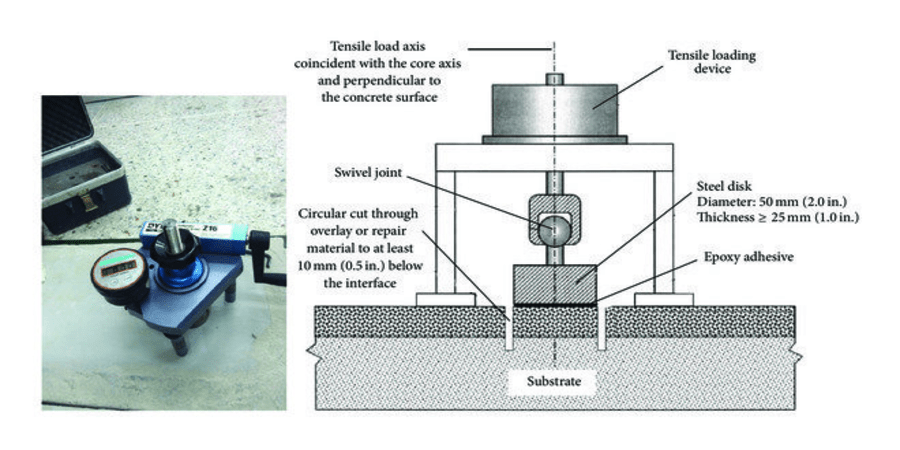

Apply adhesive to a wooden puck and attach it to a metal surface for an ASTM D4541 test. After the glue has dried, score the puck’s surrounding area with a knife and then fasten an adhesion testing tool to the puck. Pressure is applied to the puck using the testing apparatus, progressively and steadily increasing until it is released. Once the puck is released, the pull-off strength can be calculated by dividing the peak load in pounds by the square inches of the puck.

Other Adhesion Testing Methods

Several adhesion testing methods, similar to ASTM D4541, can be used to test adhesion strength. Pull-off tests, tape tests, scratch tests, cross-tests, and other techniques are all available for adhesion strength tests.

Sample Size and Result

The sample size & result analysis for the ASTM D4541 pull-off strength test are as follows:

| Particulars | Details |

| Sample size | The test length and pull rate are the two main factors considered. The pull rate must be 1 MPa/s (150 psi/s) or less, and the test must be completed in less than 100 seconds at the chosen rate. |

| Result | The sample factors enable testers to grasp a material’s pull-off strength more thoroughly by helping them better understand how much force a material can endure over time. |

Applications of ASTM D4541

The ASTM D4541 pull-off test has broad applications across several industries:

Aerospace

Aircraft coatings, including anti-corrosion and thermal barrier coatings, are tested to ensure adhesion under extreme conditions, such as high speeds and temperature fluctuations.

Marine Industry

We test coatings applied to ships, submarines, and other marine structures to ensure they can withstand prolonged exposure to saltwater, which accelerates corrosion.

Automotive Industry

Paints, corrosion inhibitors, and other coatings applied to vehicles undergo adhesion testing to ensure durability under harsh road and weather conditions.

Manufacturing

Adhesion testing is critical for machinery parts, pipelines, and other equipment. Further, it is also used where coatings are applied for protection, insulation, or functional purposes.

Furthermore, ASTM D4541 helps ensure that coatings meet industry standards, thus reducing the risk of premature failure and associated costs.

Conclusion

The ASTM D4541 test method is a reliable means of measuring the adhesion strength of a coating, which is a critical factor for the durability and functionality of a protective layer. The test method is versatile and applies to various substrates with various types of coatings. Therefore, it is helpful for many industries. Using portable adhesion testers, the ASTM D4541 test method is crucial to check how well coatings stick to metal, concrete, and other surfaces. The technique reduces maintenance costs, improves safety, and increases functionality across various applications through effective testing and evaluation.

FAQs

According to ASTM D 4541 and BS EN ISO 4624, the tensile pull-off method for adhesion testing is adhering a test dolly to the coated surface and then pulling the dolly with the coating from the substrate by applying force perpendicular to the surface.

ASTM D4541 provides guidelines for preparing, testing, and evaluating the coated systems' results to assess the sample's pull-off strength.

The pull-off strength of a material is its ability to withstand applied tension stress without failure.

Coatings applied to concrete are evaluated according to ASTM D7234, while coatings applied to metal are evaluated using ASTM D4541.

Talk to Our Experts Today!

Submit your contact info and we’ll get back to you within 24 hours

Full Spectrum of ASTM Material Testing — Backed by 2,000+ Trusted Lab Partners

ASTM standards for chemical composition, physical properties, failure analysis, and other routine and non-routine testing for polymers and plastics

ASTM standards for determination of mechanical, physical, and thermal properties, and performance of monolithic and composite ceramics

ASTM standards guiding various destructive, non-destructive and analytical tests for quality control of different metals and alloys

ASTM standards for chemical analysis of solid, liquid and gaseous materials for specification compliance and quality control

ASTM standards for various chemical, physical, stability and exposure analysis of paints and coatings

Our Services

Metrology

A variety of microscopy and spectroscopy tools available for precise measurements from the nano to the meter scale.

Learn More

Materials Testing

ASTM and ISO standard and custom chemical, mechanical, thermal, corrosion tests, etc. for all materials metals, ceramic or polymers.

Learn More

Product Testing

Thousands of tests for product quality and reliability under heat, humidity, temperature shock, vibration, drop, electrostatic discharge.

Learn More