Scope:

ASTM C730 has been made to compare Knoop indentation hardness with tensile strength, grinding speeds, and other hardness scales. Knoop hardness is one of many properties that is used for the characterization of glass.

Test Procedure:

In ASTM C730, the Knoop Indentation Hardness of Glass is an imprint of the undeformed indentation. An Indentation hardness test is done by using a calibrated machine to force a rhombic based, pointed, pyramidal diamond indenter having specific face angles, under a fixed load, into the surface of the material under test. The long diagonal of the resulting impression after removing the load is measured.

Specimen Size :

For ASTM C730, the specimen should remain intact with an indenter between the 20s and 30s. The rate of indenter motion with specimen should be 0.20 ± 0.05 mm/min and the test load should be 100gf.

Data:

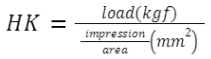

The Knoop hardness HK for ASTM C730 is calculated by using the following equation

Conclusion:

ASTM C730 is a microhardness test described to determine the Knoop indentation hardness of glass.

Talk to Our Experts Today!

Submit your contact info and we’ll get back to you within 24 hours

Full Spectrum of ASTM Material Testing — Backed by 2,000+ Trusted Lab Partners

ASTM standards for chemical composition, physical properties, failure analysis, and other routine and non-routine testing for polymers and plastics

ASTM standards for determination of mechanical, physical, and thermal properties, and performance of monolithic and composite ceramics

ASTM standards guiding various destructive, non-destructive and analytical tests for quality control of different metals and alloys

ASTM standards for chemical analysis of solid, liquid and gaseous materials for specification compliance and quality control

ASTM standards for various chemical, physical, stability and exposure analysis of paints and coatings

Our Services

Metrology

A variety of microscopy and spectroscopy tools available for precise measurements from the nano to the meter scale.

Learn More

Materials Testing

ASTM and ISO standard and custom chemical, mechanical, thermal, corrosion tests, etc. for all materials metals, ceramic or polymers.

Learn More

Product Testing

Thousands of tests for product quality and reliability under heat, humidity, temperature shock, vibration, drop, electrostatic discharge.

Learn More